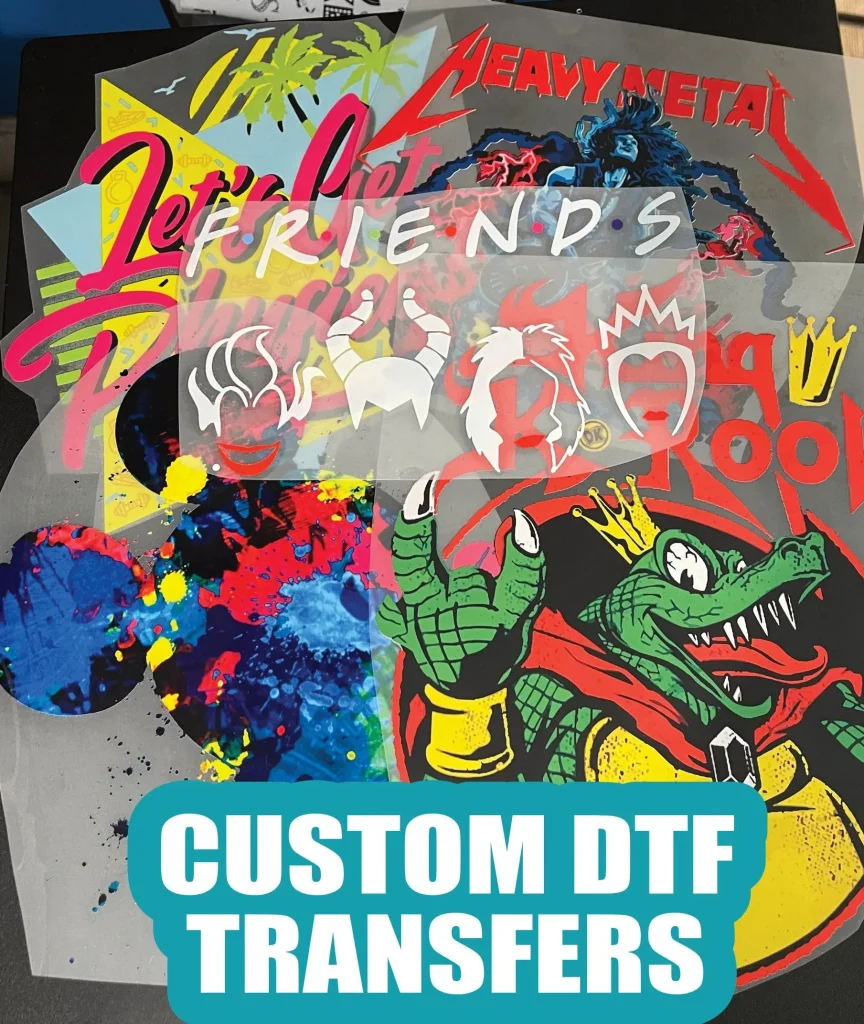

DTF transfers, or Direct to Film transfers, are transforming the textile printing landscape by combining versatility with efficiency for both small businesses and DIY enthusiasts. This innovative technique allows for stunning, vibrant designs that can easily be applied to a variety of fabrics, making it a top choice for modern printmakers. To achieve the best results in your DTF printing journey, it’s essential to grasp effective methods and expert DTF printing tips that can significantly improve your output. With the right knowledge on successful fabric transfers, including mastering your heat press and using quality inks, anyone can elevate their printing game. Join us as we explore the top strategies that will not only enhance your DTF transfers but also ensure long-lasting, beautiful results every single time.

Direct to Film printing, often referred to as DTF technology, is revolutionizing the way designs are transferred to fabrics, offering unparalleled printing capabilities for both personal and commercial applications. Commonly utilized by entrepreneurs and craft enthusiasts alike, this method enables the creation of high-quality garment prints that showcase intricate artwork with ease. Understanding the nuances of DTF printing techniques, alongside effective heat press tips, is crucial for achieving outstanding results. As we dive deeper into the best practices for fabric transfers, we’ll unveil essential insights on optimizing your printing processes. Whether you’re venturing into the world of DTF for the first time or looking to refine your existing skills, this guide will provide you with the tools needed for printing success.

Understanding the Basics of DTF Printing

To truly maximize your efficiency with DTF printing, it’s essential to start with a solid understanding of the process. Direct to Film printing allows you to create intricate designs on a special film which can then be transferred onto fabrics. This technique differs from traditional methods like screen printing, as it offers greater flexibility in colors and details. Therefore, beginners should familiarize themselves with the basic terminology and workflow associated with DTF printing, including how the ink interacts with the film and fabric.

Furthermore, getting acquainted with the equipment used in the DTF printing process is vital. Typical setups involve a high-resolution printer, a heat press machine, and high-quality inks specific to DTF applications. Understanding how each component affects the final output will empower users to make informed decisions about their materials and methods, ultimately enhancing the quality of the finished product.

Choosing Quality Materials for DTF Transfers

The quality of the materials you utilize in DTF printing cannot be overstated. Selecting high-grade DTF film is crucial for achieving vibrant and durable prints. Poor quality film can lead to unsatisfactory results, such as fading colors and ineffective transfers. To ensure your prints have the longevity and quality you desire, always invest in film that is specially manufactured for DTF processes.

Additionally, using high-quality inks specifically formulated for DTF will yield far better results than generic options. These specialized inks provide superior color vibrancy and adherence, crucial for ensuring that your prints last through washes and wear. By prioritizing quality materials, you set a solid foundation for successful DTF transfers and satisfied customers.

Effective Printer Calibration for Perfect Results

One of the cornerstones of successful DTF transfers is the proper calibration of your printer. This step is essential in achieving consistent quality and preventing issues such as color mismatches. Adjusting your printer’s settings—ink density, temperature, and other parameters—should always be based on the specific DTF film you are using. Regular calibration not only enhances print quality but also prolongs the lifespan of your equipment.

Moreover, understanding how different fabrics react to the ink can lead to better calibration strategies. For example, certain textiles might require different ink settings for optimal adhesion. Mastering printer calibration will allow you to fine-tune your process, paving the way for professional-grade prints that meet the high expectations of today’s market.

Preparing Fabrics for Optimal Adhesion

Before you can achieve flawless DTF transfers, it’s imperative to prepare your fabrics properly. This involves pre-treating materials to enhance their ability to bond with ink. Fabrics like polyester often require specific treatments that optimize their surface for better dye adhesion. Neglecting this step can lead to subpar results, where prints may peel or fade prematurely.

Additionally, testing different pre-treatment methods on sample fabrics can be beneficial. Understanding the nuances of how different materials respond to pre-treatment will allow you to refine your technique, minimizing errors during the final transfer process. This attention to pre-treatment can lead to significantly improved transfer outcomes, ensuring vibrant and durable prints.

Mastering Heat Press Techniques for DTF

Heat press techniques play a pivotal role in the success of DTF transfers. Ensuring you have the correct temperature, pressure, and duration settings is vital for achieving the best adhesion and preventing damage to your design or fabric. Each type of DTF film and fabric will have unique requirements that you need to adhere to, so investing time in mastering these techniques can significantly alter the quality of your prints.

Furthermore, performing a few practice runs before tackling larger batches can help you perfect your heat press techniques. This approach allows you to identify adjustments you might need to make for specific designs or materials. Being diligent in perfecting these techniques will pay off, leading to professional results that keep your customers coming back for more.

Avoiding Common Pitfalls in DTF Printing

Even the most experienced printers can fall victim to common mistakes associated with DTF printing. Issues such as incorrect temperature settings, improper pressure during heat pressing, and using outdated inks can drastically impact the quality of your transfers. Becoming aware of these common pitfalls allows you to create a checklist to ensure you always follow best practices throughout your printing process.

Additionally, sharing insights and experiences with other printers through online forums or workshops can reveal additional pitfalls to avoid. By learning from the collective experiences within the DTF printing community, you’ll be better positioned to navigate challenges effectively and improve your overall workflow.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a printing technique that allows high-quality designs to be printed onto films before being transferred onto fabrics. The process involves printing the design onto a special film using DTF inks, applying an adhesive powder, and then using heat and pressure to transfer the design onto the fabric, resulting in vibrant and durable prints.

What are some essential DTF printing tips for beginners?

For beginners in DTF printing, essential tips include starting with high-quality DTF film, optimizing printer settings for ink density and temperature, and mastering heat press techniques. Additionally, pre-treating fabrics and conducting test prints can help ensure successful fabric transfers and minimize errors.

How do heat press tips impact the quality of DTF transfers?

Heat press tips are crucial for achieving successful DTF transfers as they determine the application of heat, pressure, and duration. Using incorrect settings can lead to poor adhesion, scorching, or incomplete transfers. Always verify the recommended heat press parameters based on the film and fabric to ensure optimal results.

Can I use any fabric for DTF printing?

While DTF printing is versatile, it works best on synthetic fabrics, particularly those made of polyester. Pre-treating fabrics can improve adhesion, but natural fibers like cotton may require special considerations. Testing different materials will help identify the best options for your DTF transfers.

What are some common mistakes when using DTF printing techniques?

Common mistakes in DTF printing include incorrect temperature settings, using low-quality inks or films, and not pre-treating fabrics adequately. Awareness of these pitfalls allows you to avoid them, ensuring successful DTF transfers and maintaining high print quality.

How can I stay updated on the latest DTF printing techniques?

To stay updated on the latest DTF printing techniques, engage with industry blogs, join forums, and connect with other printing enthusiasts in communities. Regularly exploring new materials and techniques will enhance your skills and keep your DTF transfers innovative and competitive.

| Tip Number | Tips for Successful DTF Transfers |

|---|---|

| 1 | Ensure High-Quality DTF Film: Use premium DTF film compatible with your inks for vibrant, long-lasting prints. |

| 2 | Optimize Printer Calibration: Regularly adjust your printer settings for consistent print quality. |

| 3 | Use Quality Inks: Invest in high-quality inks specifically intended for DTF printing to enhance colors and durability. |

| 4 | Pre-Treat Fabrics: Prepare fabrics beforehand to enhance dye adhesion and transfer effectiveness. |

| 5 | Master Heat Press Techniques: Verify temperature, pressure, and duration settings for optimal transfers. |

| 6 | Test Prints: Conduct preliminary prints to troubleshoot settings before full production runs. |

| 7 | Consider Design Complexity: Start with simpler designs to master DTF techniques gradually. |

| 8 | Avoid Common Mistakes: Keep track of best practices to sidestep typical pitfalls in DTF printing. |

| 9 | Keep Equipment Clean: Regular maintenance of printing equipment prevents quality issues. |

| 10 | Stay Updated on Techniques: Engage with industry updates to learn new methods and improve DTF processes. |

Summary

DTF transfers have emerged as a transformative printing method, emphasizing the importance of using high-quality materials and diligent techniques to achieve flawless results. By implementing the top 10 tips outlined above, you can significantly enhance your DTF transfers and ensure that your designs not only look stunning but also withstand the test of time. From investing in high-quality film and inks to mastering the heat press technique, each tip is crucial in maximizing your printing potential. Whether you’re just starting or looking to refine your skills, embracing these practices will lead to successful DTF transfers that delight your customers and elevate your printing projects.