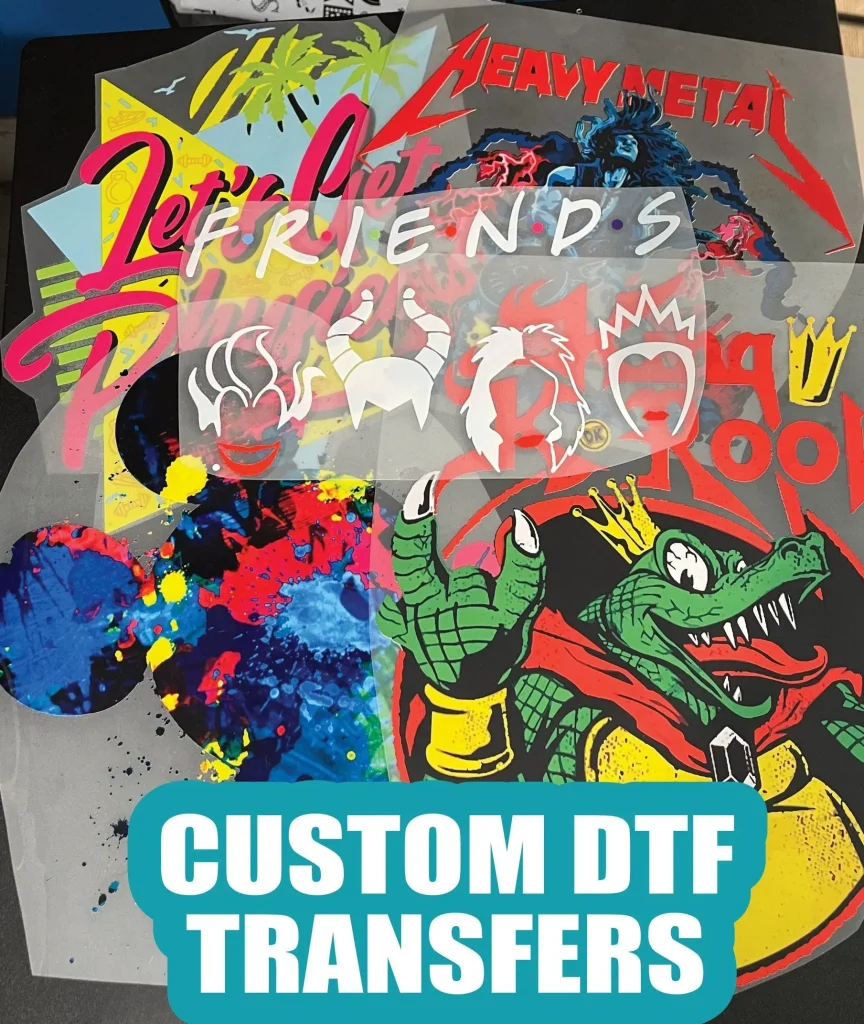

DTF transfers, or Direct-to-Film transfers, represent a groundbreaking advancement in the realm of fabric printing, delivering vibrant colors and intricate designs to apparel. This innovative technique allows artists and designers to apply eye-catching graphics on a variety of materials using advanced DTF printing techniques. As the demand for custom apparel continues to grow, understanding how to use DTF transfers effectively becomes indispensable for anyone in the industry. With capabilities to produce rich, vibrant colors that truly stand out, DTF printing is fast becoming a favorite among creators looking to elevate their products. In this guide, we will explore the essentials of vibrant color application and the best practices to maximize the stunning potential of DTF transfers.

The world of textile printing has evolved significantly with technologies like Direct-to-Film transfer, commonly known as DTF transfer, leading the charge in quality and versatility. This printing method stands out for its ability to accurately reproduce vibrant colors on different types of fabrics, making it a key tool for apparel printing DTF. For creative individuals interested in producing custom designs, learning about DTF printing techniques will provide an edge in achieving striking visuals. From choosing the best transfer films to mastering heat application, there’s much to explore in this exciting domain of fabric decoration. By leveraging the unique properties of DTF printing, you can unlock new opportunities to fabricate unforgettable apparel designs.

What Are DTF Transfers and Their Benefits?

DTF transfers, or Direct-to-Film transfers, signify a groundbreaking advancement in apparel printing techniques. Unlike traditional methods, DTF allows for high-resolution images to be printed directly onto a specialized film, which can then be effortlessly transferred onto various fabric types. This ensures not only vibrant and eye-catching colors but also exceptional durability in the printed design. Unlike sublimation, which is limited to polyester fibers, DTF transfers can be applied to cotton, blends, and more, making them highly versatile for clothing and accessory manufacturers.

The primary benefit of using DTF transfers lies in their ability to deliver rich color reproduction and intricate details that capture the nuances of original designs. With the right DTF printing techniques, designers can achieve effects that were once thought impossible with conventional printing methods. DTF transfers are particularly advantageous for custom apparel, enabling creators to showcase their unique artistry while ensuring that colors remain vivid and true over time.

Innovative Techniques to Enhance DTF Color Vibrancy

When aiming for vibrant colors using DTF transfers, choosing the right materials is paramount. High-quality transfer films specifically designed for DTF printing paired with premium inks enhance the vibrancy and longevity of the designs. Utilizing a white ink base layer is crucial, especially when working on dark or colored fabrics, as it helps to amplify the brightness and saturation of the transferred image. This technique is vital in achieving the sought-after vivid look that many designers strive for.

Additionally, implementing appropriate heat press settings can significantly influence the color outcome. Each fabric type may demand unique heat, pressure, and timing adjustments for optimal results, typically settling around 320°F for a duration of about 15 seconds. It is essential to fine-tune these parameters to your specific materials to ensure that the DTF transfers adhere properly while maintaining the integrity and vibrancy of the colors.

Comparing DTF Transfers to Other Printing Methods

When comparing DTF transfers to other printing techniques, such as sublimation, it becomes evident that DTF offers broader versatility. While sublimation works beautifully on polyester, it often falls short on natural fibers like cotton. DTF transfers eliminate this limitation, allowing for colorful designs on a wider range of fabrics without sacrificing quality. This advantage positions DTF as an ideal choice for custom apparel printing where diverse fabric use is commonplace.

Moreover, the flexibility in color layering techniques sets DTF apart. With DTF printing, designers can experiment with layering multiple colors seamlessly, creating depth and detail that allure the eye. By strategically turning layers on and off in the design software, users can build complex images that embody vibrant color combinations—an aspect that can be more difficult with other methods, thus elevating the custom design experience.

Mastering DTF Transfer Application

To master the application of DTF transfers, it is essential to prepare your fabric effectively. Pre-treating the fabric before the transfer process enhances the bonding of the DTF transfer to the textile, ultimately leading to improved color vibrancy and durability. Many professional printers endorse pre-treatment as a best practice, as it assists in achieving a more dynamic representation of designs while ensuring they withstand the test of time.

As you delve into the nuances of using DTF transfers, it’s also critical to ensure your artwork is of the highest resolution. Higher resolutions yield clearer images with sharper colors, making for a professional appearance once heat applied. By investing time in artwork preparation, you set the stage for the successful application of DTF transfers, optimizing the vibrant colors that will stand out on any apparel.

The Future of DTF Transfers in Apparel Printing

With the rapid advancements in technology, the future of DTF transfers looks promising. As more companies innovate and enhance their DTF printing technologies, we can expect not only greater accessibility but also improvements in color vibrancy and the overall user experience. Companies like Insta Graphic Systems and Sam’s DTF Transfers are leading the charge, introducing products that push the boundaries of what is possible in the world of custom apparel printing.

Furthermore, as market demand for unique and personalized apparel continues to grow, DTF transfers will inevitably play a crucial role in meeting the needs of designers and consumers alike. The ability to create bold, vibrant designs on a variety of fabrics will keep DTF transfers at the forefront of the industry, making them an invaluable tool for both novice and seasoned designers aiming to leave their mark in a competitive market.

Exploring Resources for DTF Printing Mastery

For those looking to excel in the art of DTF printing, a wealth of resources is available to guide you on your journey. Numerous tutorials, webinars, and online communities are dedicated to exploring DTF printing techniques and troubleshooting common issues. Engaging with these resources allows both hobbyists and professionals to deepen their understanding of DTF transfers, ensuring they maximize their creativity and achieve the best results through informed practices.

Additionally, many suppliers and manufacturers offer training materials and practical workshops focusing on DTF technology, which can prove invaluable for newcomers. By tapping into these resources, designers are empowered to unleash their creativity, experiment with vibrant colors in DTF transfers, and perfect their application techniques for durable, eye-catching designs that resonate in the marketplace.

Frequently Asked Questions

What are DTF transfers and how do they enhance vibrant colors in apparel printing?

DTF transfers, or Direct-to-Film transfers, are a modern printing technique enabling high-quality, detailed designs to be transferred onto various fabrics. This method allows for exceptional color reproduction, making it ideal for achieving vibrant colors in apparel printing. By printing designs on a special film and then applying them via heat, DTF transfers ensure rich and vivid hues that stand out.

How do I use DTF transfers effectively to achieve the best results?

To use DTF transfers effectively, start by selecting high-quality transfer films and inks specifically designed for DTF printing. Ensure that your heat press settings are correctly adjusted, with a recommended temperature of around 320°F for 15 seconds. Pre-treat your fabrics for better adhesion and prepare your artwork at a high resolution to maximize color vibrancy and clarity in your final design.

What advantages do DTF printing techniques have over traditional methods?

DTF printing techniques offer several advantages over traditional methods like sublimation. Unlike sublimation, which primarily works on polyester, DTF transfers can adhere to a wider variety of materials, including cotton and blends. This versatility ensures vibrant color retention across different fabric types, making DTF a flexible choice for apparel printing.

What recent innovations are improving the vibrancy of DTF transfers?

Recent innovations in DTF transfers, particularly from companies like Insta Graphic Systems and Sam’s DTF Transfers, focus on enhancing color vibrancy and durability. New products utilize advanced technology to achieve richer colors and better performance, setting new industry standards for apparel decoration. These advancements help designers create eye-catching and long-lasting prints.

Can I achieve vibrant colors on dark fabrics using DTF transfers?

Yes, DTF transfers excel at producing vibrant colors on dark fabrics by using a white ink base layer. This technique increases brightness and saturation, allowing vibrant colors to stand out even on darker materials. The ability to print effectively on various fabric types, including those with color, is one of the key benefits of DTF printing.

What tips can enhance color vibrancy in DTF printing?

To enhance color vibrancy in DTF printing, use high-quality inks and transfer films, and ensure your heat press is set to the appropriate temperature and pressure. Layering techniques can also help build depth in colors, while pre-treating fabrics improves ink adhesion for better longevity. Additionally, always work with high-resolution artwork to ensure clarity and sharpness in your printed designs.

| Key Point | Details |

|---|---|

| What are DTF Transfers? | DTF (Direct-to-Film) transfers are a modern fabric printing method that applies high-quality designs to textiles using a special film and heat transfer. |

| Recent Innovations | Insta Graphic Systems and Sam’s DTF Transfers are notable for advancing DTF technology, providing exceptional color vibrancy and service speed. |

| DTF vs. Sublimation | DTF transfers offer better compatibility with various materials, including cotton and blends, unlike sublimation which is limited to polyester. |

| Techniques for Vibrancy | 1. Use high-quality inks and films. 2. Adjust heat press settings appropriately. 3. Utilize color layering techniques in designs. 4. Pre-treat fabrics for better transfer adherence. 5. Prepare artwork at high resolution for optimal results. |

Summary

DTF Transfers are transforming the landscape of custom apparel decoration by providing designers with a versatile and effective method for creating vibrant, eye-catching prints. With the advancements brought forth by companies like Insta Graphic Systems and Sam’s DTF Transfers, users can expect unmatched color vibrancy and durability in their designs. By employing best practices such as using high-quality materials, perfecting heat press settings, and ensuring meticulous artwork preparation, anyone can unlock the true potential of DTF transfers. As this technology continues to evolve, it empowers both amateur and professional designers to produce striking garments that stand out in the competitive market.