In the realm of custom apparel printing, DTF transfers are revolutionizing the industry with their unique advantages. Direct-to-Film (DTF) printing stands out for its high-quality prints, allowing for vibrant and detailed designs that capture the consumer’s eye. This sophisticated technique not only accommodates a variety of fabric types but also utilizes eco-friendly printing methods, making it an attractive choice for environmentally conscious brands. Understanding the DTF printing benefits can help businesses stay competitive in a dynamic market, ensuring client satisfaction with durable products that withstand the test of time. As we delve deeper into the world of DTF transfers, it becomes evident why they are fast becoming the preferred printing solution for many garment decorators.

Also known as Direct-to-Film transfers, this innovative printing method has become a game changer in the custom textile printing industry. Renowned for delivering exceptional print quality, DTF printing allows brands to express intricate designs with precision and clarity. With sustainability being a growing concern, many businesses are turning to this approach for its eco-friendly characteristics, promoting a responsible choice in their production process. Furthermore, the flexibility and cost-effectiveness of using DTF transfers make them an appealing option for entrepreneurs and established businesses alike. By embracing this advanced printing technology, companies can enhance their offerings while meeting the diverse needs of their clientele.

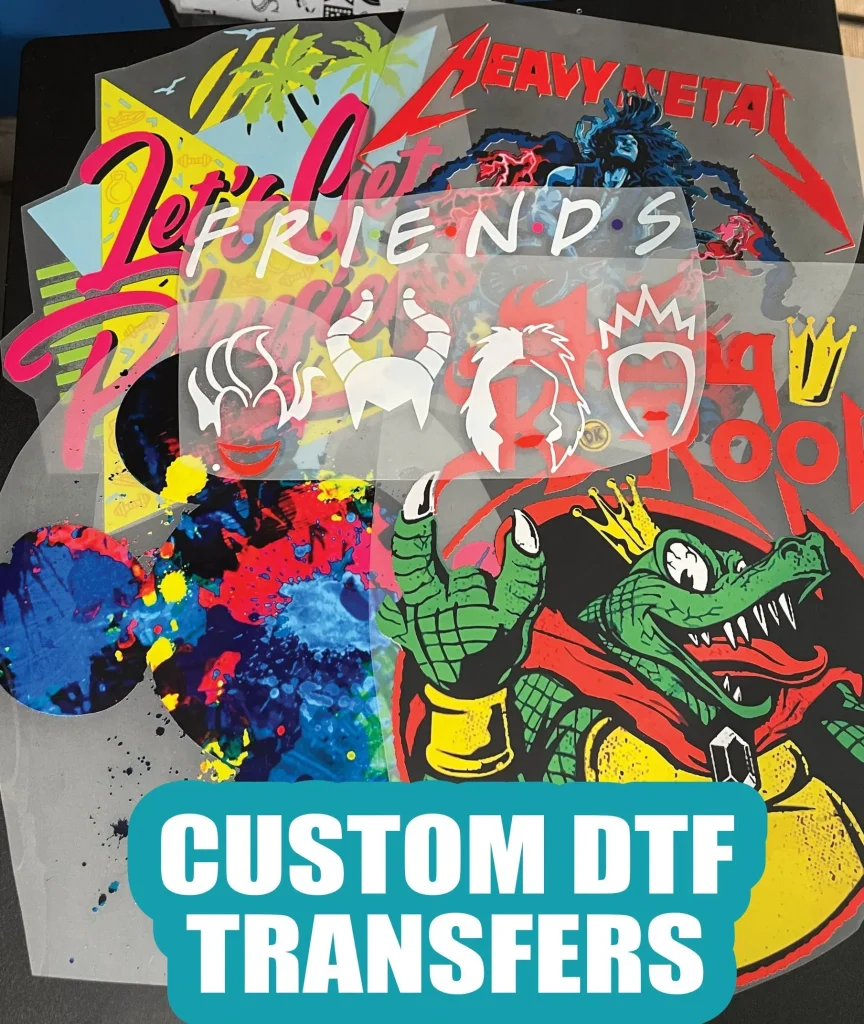

Understanding DTF Transfers: A Modern Printing Solution

DTF (Direct-to-Film) transfers represent an innovative approach in the realm of custom apparel printing. This technique employs a unique method of printing designs onto a specialized film, which is then transferred onto various fabrics using heat and pressure. The process is not only efficient but also allows for exceptional clarity and detail in the designs, making it especially beneficial for intricate artwork and patterns that might be challenging to replicate using traditional techniques. The growing demand for personalized apparel has further propelled the popularity of DTF transfers, as they provide a reliable solution to meet the rising expectations of consumers.

In addition to its primary function, DTF transfers offer significant versatility across a wide range of materials beyond just textiles. Whether it’s cotton, polyester, or blended fabrics, DTF technology excels across the board, catering to diverse business needs. This adaptability allows fashion brands to explore various product formats, from T-shirts and hoodies to bags and home textiles, expanding their market reach and enhancing customer satisfaction through customized options.

Benefits of DTF Printing for Custom Apparel

The primary benefit of DTF printing lies in its ability to produce high-quality prints that meet the visual demands of today’s consumers. With vivid colors and sharp details, DTF transfers significantly enhance the aesthetic appeal of custom apparel. This printing method employs water-based inks, which provide a soft feel on garments while ensuring that the colors remain vibrant after multiple washes. For businesses looking to command higher price points and cater to discerning customers, the quality that DTF printing offers is a definitive advantage.

Another advantage is that DTF printing is capable of handling complex designs with ease, making it ideal for graphic artworks, logos, and patterns. Unlike traditional methods that may dilute or misinterpret fine lines, DTF printing preserves the integrity of the artwork, delivering stunning results that can elevate a brand’s identity. As a result, apparel businesses can confidently offer high-value products that resonate with customers, fostering brand loyalty and repeat purchases.

A Cost-Effective Approach to Custom Apparel Production

When it comes to production costs, DTF printing emerges as a more economical option compared to many traditional printing techniques. The expenses associated with setup are lower, making it a practical choice particularly for small to medium-sized businesses aiming to minimize their initial investment. Furthermore, DTF printing allows for batch production of transfers, enabling brands to efficiently manage inventory and reduce waste—an essential factor in enhancing profit margins.

For startups and small enterprises, the affordability of DTF printing can be a game changer. It provides the flexibility to produce custom apparel without the hefty costs typically associated with methods like screen printing. Being able to offer small runs of unique designs without prohibitive costs opens up new opportunities for creativity and customization in the competitive apparel market, allowing brands to differentiate themselves and meet niche consumer demands.

Simplicity and Speed of DTF Printing Process

The DTF printing process is characterized by its simplicity and efficiency, which are crucial for meeting the fast-paced demands of today’s retail environment. The ability to print designs onto film and transfer them in a streamlined manner significantly reduces production times compared to other methods. Businesses leveraging DTF technology can respond quickly to consumer trends and custom requests, which boosts their competitive advantage in the market.

In an industry where quick turnaround times are often necessary, DTF printing plays a vital role. It allows businesses to fulfill orders promptly without sacrificing quality, as the DTF prints maintain durability and vibrant color retention even as they speed through the production line. This balance of speed and quality is essential in today’s on-demand economy, where consumers increasingly expect instant gratification and personalized products.

The Durability of DTF Transfers: A Selling Point for Brands

Durability is a critical factor for both consumers and businesses in the apparel industry. DTF transfers stand out for their resilience, with prints that can withstand multiple washes without fading, cracking, or peeling. This attribute drastically reduces the chances of returns or complaints related to poor-quality prints, thus enhancing overall customer satisfaction.

For brands that prioritize quality and longevity in their products, emphasizing the durability of DTF prints can be a compelling marketing point. Customers increasingly seek garments that are not only stylish but also capable of withstanding the rigors of everyday wear. By offering durable custom apparel, businesses can build trust and ensure repeat purchases from satisfied customers.

Eco-Friendly Aspects of DTF Printing

In an age where sustainability is at the forefront of consumer consciousness, the eco-friendly attributes of DTF printing represent a significant draw for many businesses. The primary use of water-based inks in DTF transfers means that these prints produce lower environmental waste compared to traditional solvent-based methods. This characteristic aligns with the growing consumer preference for environmentally responsible products, making DTF an attractive option for brands looking to establish eco-friendly practices.

Moreover, brands that embrace sustainable printing methods can enhance their image and appeal to socially conscious consumers. The ability to showcase commitment towards reducing environmental impacts not only attracts eco-minded customers but also bolsters brand loyalty. By integrating DTF printing into their production processes, businesses can align with contemporary values and trends that prioritize sustainability, setting themselves apart in a crowded market.

Frequently Asked Questions

What are the main benefits of DTF transfers in custom apparel printing?

DTF transfers offer numerous benefits for custom apparel printing, including high-quality prints with vibrant colors and intricate designs. The material versatility allows printing on cotton, polyester, and even leather, making it ideal for diverse product lines. Furthermore, DTF printing is cost-effective for small runs and provides faster turnaround times compared to traditional methods, all while ensuring durability and eco-friendly options with water-based inks.

How does DTF printing ensure high-quality prints?

DTF printing ensures high-quality prints through its advanced process that creates detailed, vibrant, and high-resolution images. The use of water-based inks provides a soft feel on fabrics, essential for consumer satisfaction, and is particularly effective for intricate designs featuring fine details and gradients, making it an excellent choice for custom apparel.

Is DTF printing eco-friendly compared to other printing methods?

Yes, DTF printing is considered eco-friendly as it primarily uses water-based inks, which generate less environmental waste than solvent-based inks used in traditional methods. This environmentally responsible approach appeals to consumers who prioritize sustainability, making DTF transfers a suitable option for businesses aiming to align with eco-conscious values.

How does the versatility of DTF transfers benefit businesses?

The versatility of DTF transfers allows businesses to print on a variety of materials, including cotton, polyester, leather, and more, catering to diverse customer needs. This capability enables companies to expand their product offerings and tap into new markets, which is beneficial for enhancing market competitiveness and driving sales.

What makes DTF transfers a cost-effective option for printing?

DTF transfers are cost-effective due to lower setup costs and the ability to perform batch printing, which minimizes waste and reduces overall production expenses. This is especially advantageous for startups and small businesses that may have limited budgets, allowing them to produce high-quality prints without incurring significant debt.

Why is the speed of the DTF printing process advantageous for businesses?

The speed of the DTF printing process provides businesses with a competitive edge by enabling quicker turnaround times for custom orders. This efficiency is crucial in today’s fast-paced market where customers expect rapid delivery, allowing businesses to meet demands promptly while maintaining high-quality standards in custom apparel.

| Key Points | Description |

|---|---|

| Quality Prints | DTF transfers produce high-resolution images with vibrant colors, suitable for intricate designs. |

| Material Versatility | Compatible with various textiles (cotton, polyester) and other substrates (leather, plastics), expanding product offerings. |

| Cost-Effectiveness | Lower setup costs, ideal for small to medium production runs, minimizing waste and maximizing profits. |

| Simplicity and Speed of Process | A straightforward printing method that allows for quick turnaround times, catering to on-demand orders. |

| Durability | DTF prints are resistant to fading and cracking, withstanding multiple washes, enhancing customer satisfaction. |

| Eco-Friendly Options | Utilizes water-based inks, generating less waste, appealing to environmentally conscious consumers. |

Summary

DTF transfers stand out in the world of printing technology due to their remarkable versatility and quality. Direct-to-Film (DTF) transfers boast exceptional print quality, enabling businesses to produce detailed designs with vibrant colors that cater to diverse customer needs. The versatility of DTF printing extends across multiple materials, making it suitable for textiles and beyond, which allows businesses to diversify their product offerings. Additionally, the cost-effectiveness of DTF transfers, particularly for small to medium runs, provides a practical solution without sacrificing quality. The simplicity of the printing process combined with its quick turnaround times positions DTF transfers as a favored choice for fulfilling custom orders. Durability and eco-friendly options further enhance their appeal, ensuring that products can withstand regular use while being mindful of environmental concerns. As the printing industry evolves, DTF transfers are sure to play a significant role in shaping the future of custom apparel and textile printing.