DTF transfers, or Direct-to-Film transfers, are revolutionizing the way designs are applied to fabrics, making them an exciting option for aspiring printers and entrepreneurs. This innovative process allows for high-resolution images with stunning colors to be printed directly onto a special film, which can then be transferred onto various materials using heat. For those dabbling in the print-on-demand DTF market, mastering the DTF transfer process can mean the difference between mediocre and eye-catching results. In this DTF printing guide, we’ll explore the immense potential and growing popularity of this technology, highlighting its ease of use and profitability. Whether you’re interested in customizing apparel or launching your own merchandise line, understanding DTF transfers is key to unlocking a world of creative possibilities.

Also known as Direct-to-Film printing, this method is akin to a creative chemistry where vibrant graphics meet fabric in a seamless transfer process. By employing specialized printers to produce high-quality images that adhere firmly to various textiles, DTF offers versatility that traditional methods often lack. Entrepreneurs and hobbyists alike are drawn to this emerging trend, making print-on-demand applications more accessible and efficient than ever before. With the right knowledge on how to DTF transfers work, users can tap into a lucrative market, appealing to consumers’ demands for personalized and unique products. Exploring the details of this innovative printing approach unveils an exciting avenue for anyone looking to make a mark in the custom garment industry.

Understanding the Basics of DTF Transfers

DTF transfers, or Direct-to-Film transfers, revolutionize the way we think about custom designs on fabrics. At its core, the DTF process involves printing a design onto a specialized film that can then be applied to various materials, from cotton to polyester and more. This method not only allows for vibrant and intricate designs but also offers a level of durability that many other printing techniques struggle to achieve. For beginners, grasping the foundational principles of DTF transfers is essential to harnessing their full potential.

One important aspect of understanding DTF transfers is the technology behind them. Direct-to-Film printing utilizes advanced printer technologies that facilitate high-quality outputs, even for novice users. By employing vibrant inks and specialized printers, the DTF process is able to produce an impressive color saturation that can translate into stunning finished pieces, making it an attractive option for artists and entrepreneurs looking to create unique merchandise.

Why Choose DTF Transfers for Your Business?

The choice to utilize DTF transfers over traditional methods, such as screen printing, is driven by several key advantages. Firstly, DTF printing is more cost-effective, especially for small runs or custom designs. This affordability allows budding entrepreneurs and hobbyists to produce high-quality items without significant upfront investments in equipment and materials. Furthermore, DTF supports a wide variety of fabric types, enabling businesses to cater to different customer needs — from cotton t-shirts to polyester sportswear.

Additionally, the quick turnaround time associated with DTF transfers makes this method particularly appealing for print-on-demand operations. Once the designs are printed and cured, they can be heat pressed onto fabric in minutes, allowing businesses to fulfill orders rapidly. This efficiency not only enhances customer satisfaction but also encourages repeat business as consumers find the products durable and well-made.

Exploring the DTF Transfer Process: A Beginner’s Guide

For anyone looking to dive into the world of DTF transfers, it is crucial to understand the step-by-step process involved. The DTF transfer process begins with image preparation, where high-resolution graphics are selected and optimized to suit the requirements of DTF printing. Ensuring that the images are clear and vibrant is vital, as this directly impacts the final product’s appearance after the transfer is applied.

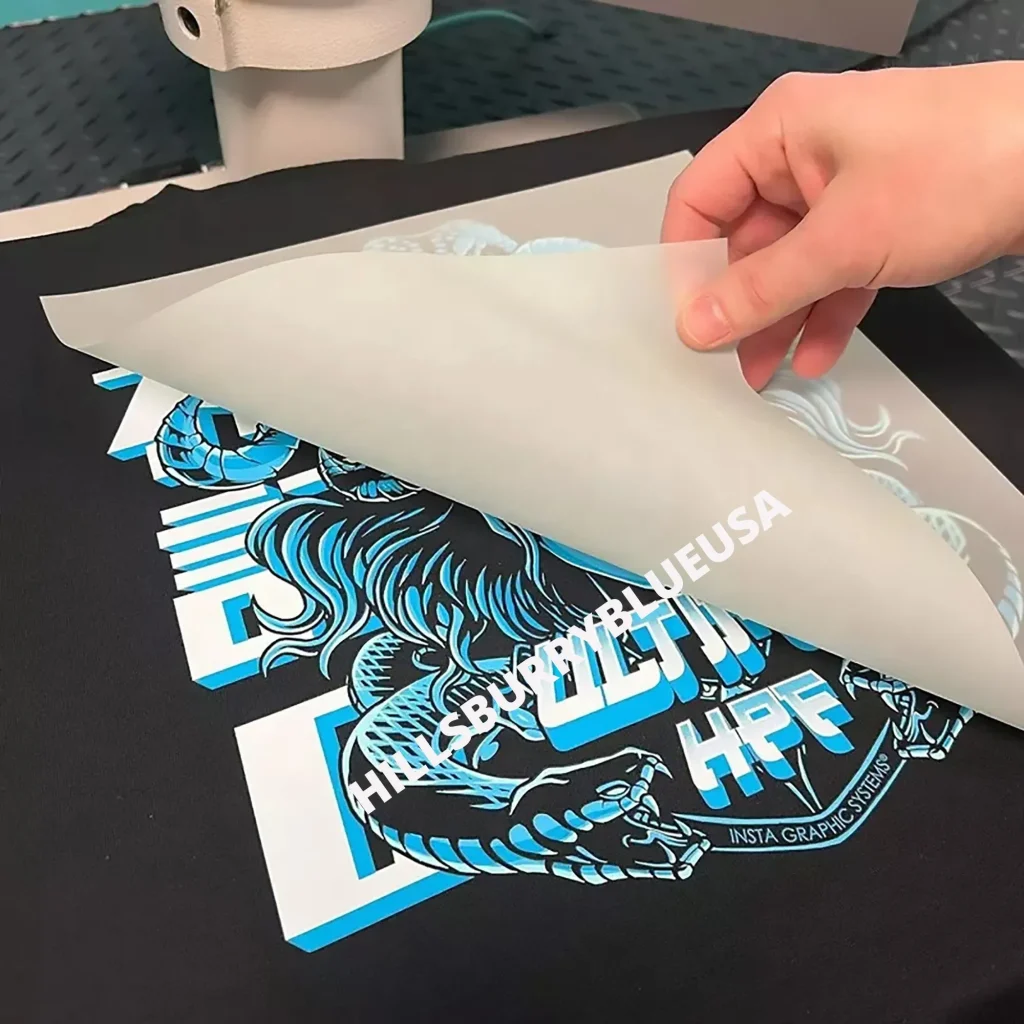

Following image preparation, the actual printing process entails using specialized DTF printers which are optimized for this purpose. Once the design is printed onto the DTF film, an adhesive powder must be applied to ensure the design adheres correctly during the heat press application. This phase is critical, as it determines both the quality of the print and its longevity on the fabric.

DTF Printing: Innovations and Trends for 2023 and Beyond

As we look towards the future, the DTF printing landscape continues to evolve with emerging innovations and trends. Recent technological advancements are driving manufacturers to produce more affordable and user-friendly DTF printers, making it easier for newcomers to enter the market. These innovations often include features that streamline the DTF transfer process, reducing setup time and enhancing print quality.

Another trend to watch is the increasing versatility of materials suitable for DTF transfers. While polyester has traditionally dominated the market, advancements in DTF adhesive technology now allow for successful transfers on a broader range of fabrics. This expanded material compatibility opens new opportunities for businesses to innovate and diversify their product offerings, catering to more niche markets and customer preferences.

Maximizing Quality and Durability with DTF Transfers

One of the standout features of DTF transfers is their impressive durability and wash resistance. This characteristic is primarily due to the quality of the materials used in the process, such as specialized transfer films and high-quality inks. For beginners, understanding how to achieve the best results hinges on selecting the right combination of materials and adhering to proper application techniques.

To maximize the durability of DTF prints, it is essential to follow the correct curing and heat press guidelines. Each fabric type may require slightly different conditions for the adhesive to bond effectively with the fibers. By investing time in learning these specifics, users can ensure that their products stand the test of time, leading to higher customer satisfaction and minimizing return rates.

Getting Started with Print-on-Demand DTF Transfers

Venturing into print-on-demand using DTF transfers can be an exciting opportunity for both creative entrepreneurs and hobbyists. This model allows users to produce custom designs without holding large inventories, significantly cutting overhead costs. By leveraging the DTF printing method, individuals can provide personalized products that meet the rising demand for unique consumer goods.

To effectively start a print-on-demand business with DTF transfers, it is important to familiarize oneself with the entire workflow from design creation to product fulfillment. This includes sourcing high-quality DTF printers and materials, mastering the transfer process, and establishing strong marketing strategies. Engaging with communities of like-minded individuals can also provide valuable insights and support as newcomers navigate the challenges and rewards of this business model.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process involves several key steps: first, a design is printed onto a special film using a DTF printer. This must include a layer of white ink to ensure vibrancy. Next, a hot-melt adhesive powder is applied to the printed film, which is then cured with heat to solidify the adhesive. Finally, the film is placed onto fabric using a heat press, adhering the design effectively. This method is known for its high-quality prints and durability.

How do I create DTF transfers at home?

To create DTF transfers at home, start by selecting a high-resolution image and converting it to a DTF-friendly format. Next, print the design using a DTF printer on a special film, ensuring to include white ink. After printing, apply hot-melt adhesive powder to the design, cure it with heat, and finally, use a heat press to transfer it onto your desired fabric. Following these steps allows anyone to successfully create DTF transfers.

What are the advantages of using DTF printing over traditional methods?

DTF printing offers several advantages over traditional methods such as screen printing. It is more cost-effective and requires less setup, making it ideal for small businesses and print-on-demand options. Additionally, DTF transfers can be applied to a wider variety of materials, including polyester blends, and they provide superior print durability and wash resistance.

Can I use DTF transfers on different types of fabrics?

Yes, DTF transfers are exceptionally versatile and can be applied to a range of fabrics including cotton, polyester, and blends. This makes DTF printing suitable for various projects such as custom apparel and promotional items, catering to diverse customer preferences.

What should I consider when purchasing a DTF printer?

When purchasing a DTF printer, consider factors such as the printer’s print quality, ease of use, and compatibility with DTF transfer films. Additionally, look for models that include features tailored for beginners, as well as support for a wide range of materials. Technological advancements have made it easier to find affordable and efficient DTF printers.

How can I ensure the quality of my DTF transfers?

To ensure the quality of your DTF transfers, start with high-resolution images, and use quality DTF films and inks. Properly apply the hot-melt adhesive powder and follow curing times precisely. Lastly, using a reliable heat press with the correct temperature and pressure settings will help achieve vibrant, durable prints.

| Key Point | Description |

|---|---|

| Definition of DTF Transfers | DTF transfers, or Direct-to-Film transfers, allow intricate designs to be printed onto film and then transferred to various materials using heat. |

| Growing Adoption | Increasing use by small businesses for cost-effective printing solutions using minimal setup. |

| Technological Advancements | Recent improvements in printer technology have made DTF printing more accessible and affordable for beginners. |

| Material Versatility | DTF transfers can be applied to various materials, including polyester, broadening market opportunities. |

| Quality and Durability | DTF transfers exhibit excellent wash resistance, ensuring longevity and customer satisfaction. |

| Step-by-Step Process | Involves preparation, printing, adhesive application, curing, and heat press execution for final transfer. |

Summary

DTF Transfers have transformed the world of textile printing by offering an innovative solution for both beginners and established businesses. This technique not only broadens creative possibilities with high-quality prints but also serves as a versatile option for various materials. As the popularity of DTF Transfers continues to rise, it is essential for aspiring entrepreneurs to embrace this method and understand its practical applications, ensuring they stay ahead in the competitive printing landscape. With its affordability, durability, and ease of use, DTF Transfers present a unique opportunity for anyone looking to venture into personalized merchandise or print shop ownership.