DTF transfers, a groundbreaking innovation in custom apparel, are transforming the landscape of garment printing through the direct-to-film (DTF) technique. This method allows vibrant and intricate designs to be printed on a special film, which is then seamlessly transferred onto fabric, providing exceptional clarity and color saturation. In this guide, you’ll discover the numerous DTF printing benefits that cater to hobbyists and small businesses alike, making it an appealing choice for those looking to venture into custom apparel printing. We will explore the DTF printing process in detail, showcasing how this advanced DTF printing technology enables rapid and cost-effective production. It’s time to unleash the full potential of your creativity with DTF transfers and delve into the endless possibilities they offer for personalized fashion and unique branding.

Unveiling the wonders of Direct-to-Film technology, the world of custom garment printing is experiencing a significant evolution. Often referred to as DTF printing, this innovative transfer method leverages specialized films to create stunning visuals that adhere brilliantly to various textile materials. As we explore the distinct advantages of this process, you will find that the efficiency and flexibility of the DTF printing approach make it the preferred choice for countless entrepreneurs and artists. This topic not only addresses the mechanics of how DTF transfers function but also highlights the impact of this revolutionary printing method on custom apparel markets. Join us as we navigate through the rich features and practical applications of this remarkable custom printing solution.

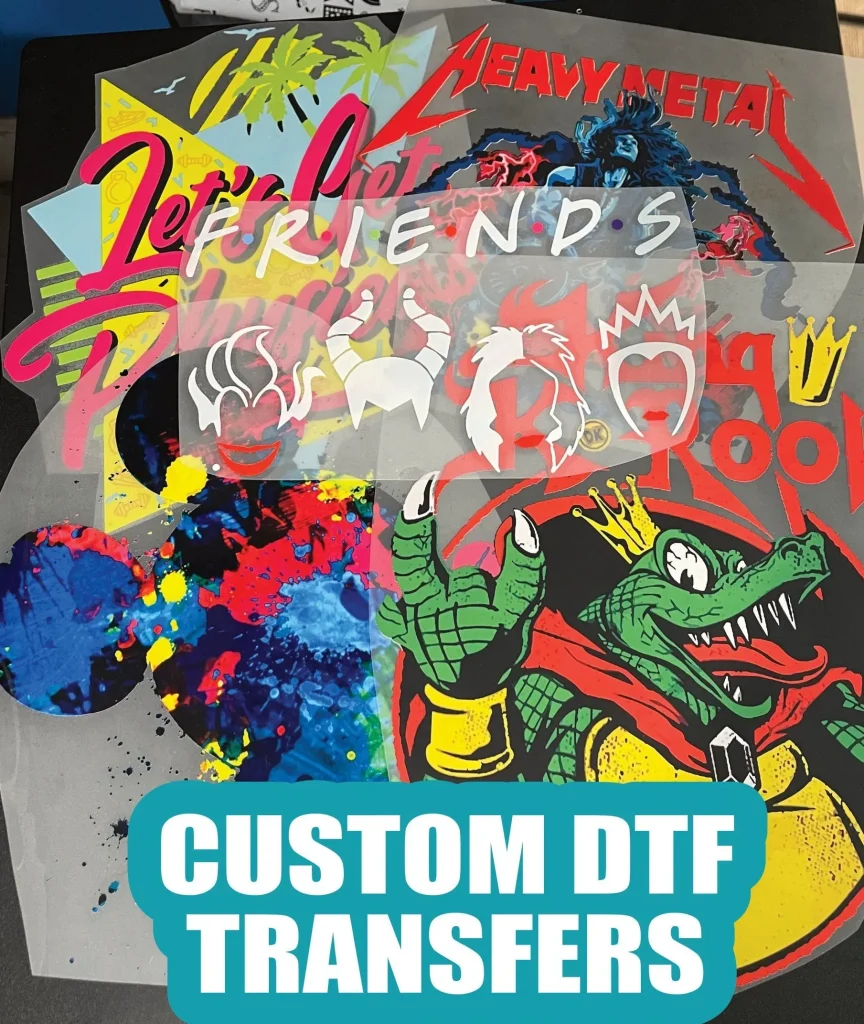

Understanding DTF Transfers and Their Process

DTF Transfers, or Direct-to-Film prints, utilize a meticulous process that significantly differs from conventional printing methods. The primary step involves printing the desired designs directly onto a specially designed film using advanced DTF printer technology. This film acts as a medium for transferring the ink onto various fabrics, ensuring an accurate representation of complex colors and patterns. After the design is printed, a powdered adhesive is applied and, through the application of heat and pressure, the design is meticulously transferred to the fabric. This process not only guarantees vibrancy and clarity but also enables compatibility with a diverse range of materials including cotton, polyester, and blends.

The DTF printing process stands out due to its accessibility and efficiency. By simplifying the traditional printing methods, it presents an attractive option for both hobbyists and entrepreneurs venturing into custom apparel printing. With intuitive steps and no extensive prior training needed, even novices can begin creating high-quality custom apparel. As DTF technology continues to evolve, understanding the nitty-gritty of this process becomes essential for those looking to harness its potential.

The Advantages of DTF Printing Technology

When evaluating the many printing options available, the benefits of DTF printing technology become glaringly apparent. One major advantage is its user-friendly nature, allowing users with minimal experience to produce intricate designs with ease. Compared to methods like screen printing which often require significant setup and material investment, DTF presents a streamlined alternative that rapidly transforms concepts into finished products. This ease of use has made it particularly popular among small businesses and individual creators who desire quality without the extensive learning curve.

Another compelling benefit of DTF printing lies in its production quality. DTF transfers are known for their crisp, vibrant outputs, offering superior durability against fading and cracking. This ensures that garments maintain their aesthetic integrity even after repeated washes, a crucial factor for consumers seeking longevity in their apparel. Furthermore, the ability to seamlessly transfer detailed designs means businesses can cater to diverse customer preferences, thus expanding their market appeal.

Exploring Recent Developments in DTF Printing

In recent years, the DTF printing landscape has evolved significantly, with new technologies emerging that enhance the quality and efficiency of prints. Manufacturer innovations have led to specialized DTF printers that offer improved speed and better ink formulations. These advancements ensure that the prints are not only more vibrant in color but also adhere more effectively to fabrics, contributing to a better end-user experience. Regular updates in technology have made DTF printing more reliable, making it an appealing option among graphic artists and entrepreneurs alike.

Moreover, recent developments also include advancements in ink quality that allow for a wider color gamut, expanding the possibilities for custom apparel. Brands and customers voicing their needs have impelled manufacturers to continue refining their processes. As more players enter the market with innovative DTF solutions, we can anticipate even greater efficiencies, reduced waste, and higher quality outputs, solidifying the position of DTF printing as a leading choice in the custom printing market.

Understanding Market Trends in DTF Printing

The custom apparel industry has seen a notable surge in demand for DTF printing, leading to a favorable market trend for this innovative technology. As consumers increasingly seek personalized and distinctive products, DTF transfers have become the go-to solution for delivering unique merchandise swiftly. This trend aligns with the rise of e-commerce, where brands can cater directly to consumer desires through on-demand printing solutions, providing businesses with an edge in the competitive landscape.

Currently, small businesses are flocking to DTF technology primarily due to its affordability and accessibility, allowing startups to enter the custom market without overwhelming initial costs. As research predicts growth in the DTF sector, especially amid rising consumer trends toward custom goods, entrepreneurs who embrace DTF printing technology will be well-positioned to leverage the ongoing demand for personalized apparel. Consequently, understanding these market trends is crucial for anyone looking to capitalize on this burgeoning industry.

Steps to Launch Your DTF Printing Business

If you are contemplating starting a DTF printing business, it begins with selecting the right equipment that aligns with your creative goals. Investing in a quality DTF printer is imperative; assess features that meet your printing and design needs. In addition, selecting high-quality DTF films and inks significantly influences the overall print quality and durability of your products. A focused approach on quality materials will ensure your prints retain their aesthetic appeal for longer, thereby increasing customer satisfaction.

Beyond equipment selection, mastering the DTF printing workflow is critical for success. Familiarizing yourself with the process—from design creation to the utilization of heat presses—is essential for delivering high-quality results. Furthermore, leveraging design software can aid in creating eye-catching visuals that resonate with your target market. Starting with smaller print runs can provide valuable insights into customer preferences while minimizing risks associated with larger investments.

The Future of DTF Transfers in Custom Apparel

Looking ahead, the future of DTF transfers in the custom apparel market appears exceptionally bright. With ongoing advancements in technology, we can expect even greater improvements in print quality, efficiency, and user experience. As more brands recognize the benefits of adopting DTF printing, it is likely to solidify its presence as a standard printing method in the industry. Innovations such as more environmentally friendly inks and processes are also on the horizon, aligning with growing consumer preference for sustainable products.

As businesses adapt to the future landscape of custom apparel printing, DTF technology will play a pivotal role in meeting consumer demands for quality and speed. The resilience of DTF printing amidst evolving market trends suggests that it will not only remain a popular choice but will likely expand into new applications and uses within the creative sectors. Those engaging with DTF technology now will position themselves at the forefront of the craft, ultimately benefiting in a rapidly changing industry.

Frequently Asked Questions

What are DTF transfers in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, are a printing method that allows high-quality designs to be printed on a specialized film and then transferred onto fabrics using a heat press. This technique is versatile and compatible with various materials, making it a go-to option for custom apparel printing.

What are the key benefits of DTF printing technology?

DTF printing technology offers numerous benefits, including vibrant color output, durability, and ease of use. Compared to traditional methods, DTF transfers provide rapid production cycles and are cost-effective, making them ideal for both small businesses and individual creators.

How does the DTF printing process work?

The DTF printing process involves printing your design onto a film, applying a powder adhesive, and then using a heat press to transfer the design onto the fabric. This method ensures that prints are vivid and resistant to fading and cracking, offering long-lasting quality.

Why is DTF printing becoming popular for custom apparel?

DTF printing is gaining popularity in custom apparel due to its affordability and the ability to produce high-quality designs quickly. With increasing consumer demand for personalized products, businesses enjoy the flexibility and efficiency that DTF transfers provide.

What should I consider when starting DTF printing for my business?

When starting DTF printing, consider investing in quality DTF printers and high-quality films and inks. Familiarize yourself with the printing process and utilize design software that aligns with DTF technology to create appealing graphics for your custom apparel.

How has DTF printing technology evolved recently?

Recently, DTF printing technology has seen significant advancements with new specialized printers and inks designed for improved quality and reliability. These developments enhance color vibrancy and adhesion, making DTF transfers a preferred option for custom apparel solutions.

| Key Points | Description |

|---|---|

| What are DTF Transfers? | DTF printing allows designs to be printed on a special film and transferred onto fabrics using heat. It works with various materials and is simple to use. |

| Key Benefits | 1. **Ease of Use**: Simplifies the printing process making it accessible for hobbyists and small businesses. 2. **High-Quality Output**: Produces vibrant colors that are durable and resistant to wear. 3. **Rapid Production Cycle**: Facilitates quick turnaround times, ideal for on-demand and bulk orders. 4. **Affordability**: Low equipment costs make it an attractive option for startups. |

| Recent Developments | New printer models and inks have improved print quality and adherence, increasing customer satisfaction and reducing waste. |

| Market Trends | The custom apparel market is growing, making DTF transfers a preferred choice for businesses looking to offer personalized products while minimizing costs. |

Summary

DTF Transfers are revolutionizing the custom printing landscape with their ability to produce stunning, high-quality designs efficiently and cost-effectively. This method, characterized by its ease of use and compatibility with various fabrics, is transforming how custom apparel is produced, making it accessible to a broader range of businesses and enthusiasts. As technology continues to evolve, the demand for DTF transfers is expected to surge, influencing trends in personalized merchandise and promotional items, ensuring that this innovative printing technique remains at the forefront of the industry.