If you’re in the business of customizing apparel, promotional items, or craft projects, UV DTF transfers offer a vibrant, durable option for achieving print-like results that stand up to daily wear, outdoor exposure, and frequent laundering. Short for ultraviolet Direct-to-Film transfers, this technology brings direct-printed quality to textiles and a range of substrates without the need for a traditional screen-printing setup, enabling faster prototyping, smaller batch production, and more flexible design iterations. Whether you’re a small-batch maker or a retailer expanding your product line, understanding sourcing options and evaluating them can save time, reduce waste, and optimize margins across multiple designs and market channels. The market offers direct-from-manufacturer programs, reputable suppliers and distributors, print shops, and online marketplaces, each with different finishes, color profiles, pricing models, minimums, lead times, and substrate compatibility to consider. By selecting a well-matched option, you’ll enjoy bright colors, crisp details, strong adhesion, and durable performance that translates into reliable products, repeat orders, and a loyal customer base.

From a terminology perspective, this approach is a film-based, UV-curable imprinting method that applies designs to fabrics with controlled heat and pressure. A practical ‘how to apply UV DTF transfers’ checklist guides the workflow, outlining pre-press prep, ideal temperatures, press times, and post-press handling to sustain color fidelity. LSI-friendly terms you might see when researching include digital-film printing on textiles, UV-curable transfers, and direct-to-film decorative processes, all pointing to the same core capability of sharp detail and strong wash performance. When evaluating suppliers, you’ll compare performance metrics such as color vibrancy, edge definition, fabric compatibility, and the ability to reproduce complex artwork across multiple substrates. In practice, selecting the right partner means balancing quality, lead times, cost, and support so your end products consistently meet customer expectations.

Understanding UV DTF Transfers: Benefits, Substrates, and Color Quality

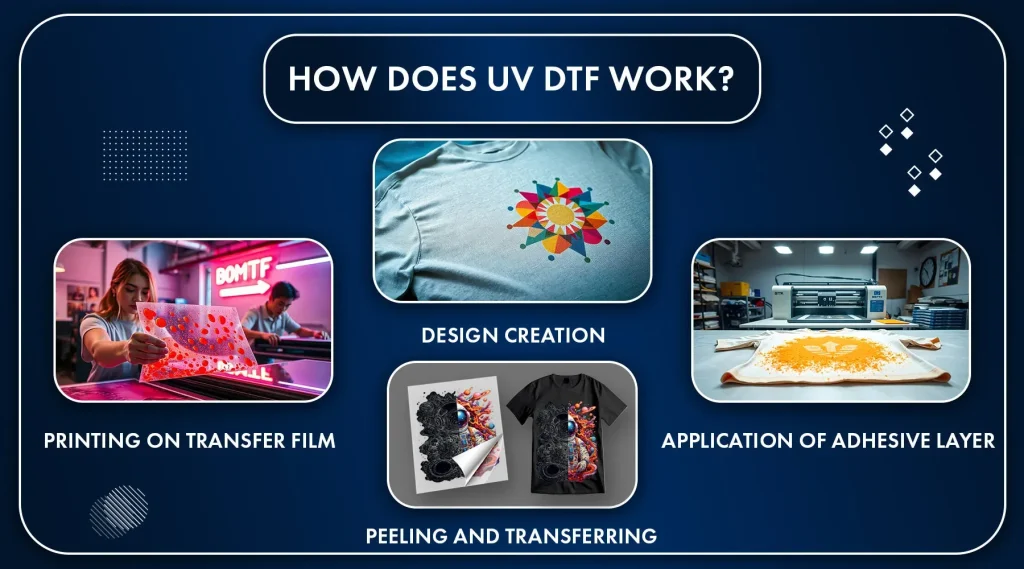

UV DTF transfers are pre-printed designs on a special film that are activated by UV light to transfer to fabrics and other compatible substrates. They combine the versatility of Direct-to-Film with the fast curing capabilities of UV inks, delivering bright colors, sharp details, and strong colorfastness across a range of textiles.

Because these transfers are film-based and cured under UV light, they typically require lower heat and shorter press times than many traditional heat-transfer methods. That can help protect delicate fabrics while producing durable results on both dark and light fabrics, expanding the kinds of materials you can customize.

How to Choose the Best UV DTF Transfers: Quality Metrics, Substrates, and Durability

To pick the best UV DTF transfers, focus on color accuracy, proofing options, and details such as edge sharpness and halftones. Ask suppliers for color proofs or swatches to compare how designs reproduce across fabrics.

Durability matters just as much as looks. Look for wash tests and adhesion data, and check substrate compatibility for cotton, cotton blends, poly blends, and specialty fabrics. The best UV DTF transfers balance vibrant finishes with a comfortable hand feel and reliable adhesion across washes.

Where to Buy UV DTF Transfers: A UV DTF Transfers Guide to Finding the Right Source

When you buy UV DTF transfers, you should explore options from direct-from-manufacturer routes, reputable UV DTF transfers suppliers, and service bureaus. The UV DTF transfers guide helps you map trade-offs between cost, lead times, and quality control.

For long-term value, look for color profiles, packaging, and clear usage guidelines. If you are shopping to buy UV DTF transfers, reading reviews and requesting color swatches can help you gauge consistency across batches.

UV DTF Transfers Suppliers: Selecting Reputable Partners and Ensuring Consistent Quality

UV DTF transfers suppliers vary in catalog depth, finish options (glossy or matte), and compatibility with different fabrics. Evaluating a supplier’s track record, after-sales support, and return policies helps reduce risk.

Establish clear expectations for lead times, minimum order quantities, and bulk discounts. A reliable supplier partnership can streamline color matching and provide ongoing troubleshooting as your needs evolve.

How to Apply UV DTF Transfers: A Step-by-Step Guide for Crisp, Durable Results

How to Apply UV DTF Transfers: Start with a clean, dry fabric and pre-press to remove moisture and wrinkles. Most UV DTF transfers respond well around 315-330°F (157-166°C) for 15-20 seconds, but always test with your specific transfer and fabric.

Ensure even, firm pressure and allow the garment to rest briefly after pressing. Following the supplier’s guidelines for cure times and post-press care helps preserve color fidelity, adhesion, and wash durability across multiple wears. If you’re wondering how to apply UV DTF transfers, this structured approach will guide you toward consistent results.

Common Mistakes with UV DTF Transfers and How to Avoid Them

Common mistakes when working with UV DTF transfers include skipping pre-press, over- or under-pressing, and neglecting substrate testing.

Mitigate these issues by performing test patches, validating color proofs, and verifying fabric compatibility across your typical product mix. This proactive approach reduces reprints, protects color integrity, and keeps customer satisfaction high.

Frequently Asked Questions

What should I look for when I buy UV DTF transfers?

Key factors include color fidelity, transfer thickness, adhesion to your fabrics, substrate compatibility, proofing options, lead times, and after‑sales support. Always request color proofs or swatches and test on representative fabrics before committing.

How do I vet UV DTF transfers suppliers to ensure consistent quality?

Vet UV DTF transfers suppliers by requesting samples, comparing proofs, and evaluating finish, color accuracy, and wash durability. Check compatibility with your fabrics, warranty terms, response time, and after‑sales support to ensure reliable partners.

What features define the best UV DTF transfers for dark fabrics?

The best UV DTF transfers for dark fabrics deliver high color density, sharp detail, strong edge definition, and durable adhesion after washing. Compare proofs across options and assess how each performs on dark substrates.

What topics are covered in a comprehensive UV DTF transfers guide?

A UV DTF transfers guide should cover technology basics, buying options (manufacturers, suppliers, service bureaus), testing and color matching, application parameters, care instructions, and common pitfalls to avoid.

What is the recommended process for how to apply UV DTF transfers?

Apply with a clean, pre‑pressed fabric; use around 315–330°F (157–166°C) for 15–20 seconds with firm, even pressure; follow the supplier’s guidelines; allow to cool, and perform a wash test to confirm durability.

How do I evaluate pricing and UV DTF transfers suppliers when deciding where to buy UV DTF transfers?

Compare pricing across tiers, check lead times and minimum order quantities, review sample programs, and assess color‑matching support, warranties, and return policies from UV DTF transfers suppliers.

| Topic | Key Points |

|---|---|

| What are UV DTF Transfers? |

|

| Why Consider UV DTF Transfers? |

|

| Where to Buy UV DTF Transfers: The Quick Guide |

|

| How to Assess UV DTF Transfers Quality Before You Buy UV DTF Transfers |

|

| Choosing the Best UV DTF Transfers for Your Project |

|

| Pricing Considerations: What to Expect |

|

| How to Apply UV DTF Transfers: A Practical Guide |

|

| Common Mistakes and How to Avoid Them |

|

| A Quick Checklist for Buyers |

|

Summary

This HTML table summarizes the key points about UV DTF transfers, including what they are, why to consider them, buying options, quality considerations, and practical application guidelines.