DTF printing techniques are transforming the world of custom apparel production, offering a unique blend of versatility and quality that appeals to both professionals and enthusiasts. This innovative approach, which stands for Direct to Film printing, allows for the creation of vibrant, high-quality prints that can be applied to a variety of fabrics. While it might seem intimidating at first, especially for those new to the craft, understanding the best practices and essential do’s and don’ts can make all the difference. In this guide, we will delve into valuable tips for DTF printing, tailored specifically for beginners, to ensure your projects yield outstanding results. Whether you’re just starting or looking to refine your skills, mastering these techniques will elevate your printing game and enhance your creativity.

Direct to Film printing, commonly referred to as DTF printing, is making waves in the custom garment industry through its ability to create stunning visuals on fabric. This method employs advanced transfer techniques that ensure durability and vivid coloration, setting a new standard for print quality. As interest in custom designs grows, tools and practices related to DTF printing continue to evolve, providing easier access for those venturing into this innovative space. By focusing on effective strategies and essential insights for DTF printing, from foundational tips suitable for beginners to professional best practices, users can confidently navigate their creative journey. Adopting these principles will not only improve your print outcomes but also deepen your understanding of apparel printing as a whole.

Understanding DTF Printing Techniques

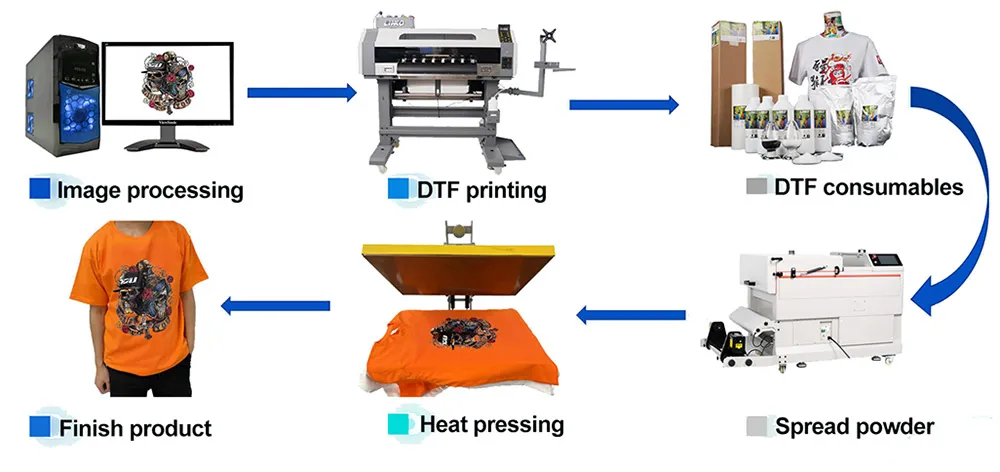

DTF printing techniques are innovative methods that offer high-quality results for fabric decoration. These techniques involve printing designs onto a special film with water-based inks. This film is then transferred onto garments using heat and pressure, creating vibrant and durable graphics. Each step of the DTF printing process requires precise handling, from selecting the right materials to ensuring the correct print settings.

To master DTF printing techniques, it’s essential to familiarize yourself with the equipment and materials used. High-quality printers and inks are crucial, as they directly impact the final output quality. Beginners can benefit from starting with standard designs before progressing to more intricate patterns, allowing a gradual learning curve that helps in setting proper temperature and pressure for optimal results.

DTF Printing Best Practices for Success

Implementing the best practices in DTF printing can significantly enhance the quality of your prints. One of the most critical steps is pre-treating the fabric, which improves ink adhesion and longevity of the print. Additionally, using premium films ensures that colors are vibrant and come out crisp and clear, avoiding issues of blurriness or fading.

Furthermore, proper curing of prints is essential for durability. This involves applying the right amount of heat for the recommended duration to set the ink correctly. Keeping notes of successful settings and experimenting can lead to discovering the perfect combination for your specific projects, making practice and experience invaluable in the pursuit of the best print quality.

Essential Tips for DTF Printing Beginners

For those just stepping into the world of DTF printing, starting off on the right foot is vital to long-term success. Beginners should prioritize understanding their printer’s specifications and capabilities while exploring online resources and communities for additional guidance. This engagement not only enhances knowledge but can also provide troubleshooting tips and best practices shared by experienced printers.

In addition, beginners should focus on ink quality and fabric selection. Quality inks result in sharper, more vibrant images, while experimenting with different fabrics can help in finding the best match for projects. As skills develop, gradually trying more complex designs will refine techniques further and lead to impressive outcomes.

Common DTF Printing Do’s and Don’ts

Navigating the do’s and don’ts of DTF printing can save you time and resources. One of the foremost do’s is to choose high-quality materials. Using inferior inks or films can compromise the print’s appearance and durability. Regularly maintaining your equipment is another essential practice; neglecting this can lead to mechanical issues that affect output quality.

Conversely, some don’ts are equally important. For example, don’t ignore the importance of temperature settings during the transfer process. Incorrect temperatures can lead to problems such as poor adhesion or fading. Additionally, avoid the temptation to overload the printer, as this can result in jams and inconsistencies, countering the benefits of DTF printing.

Trendy Designs and Creative Possibilities in DTF Printing

One of the appealing aspects of DTF printing is its versatility in design and application. From intricate graphics suitable for fashion apparel to bold, simple logos for promotional items, the design possibilities are endless. As trends in clothing and graphic design evolve, DTF printing allows creators to stay agile and produce items that resonate with current consumer preferences.

Moreover, exploring trends such as tie-dye effects or layered prints can elevate your DTF printing projects. Experimenting with various textures and fabric types can yield unique results, encouraging creativity and setting new standards within your brand. Embracing these design trends not only enhances the appeal of your prints but also aligns your offerings with market demands.

Engaging with the DTF Printing Community for Ongoing Learning

Engaging with the DTF printing community can be a transformative step in your printing journey. Online forums, social media groups, and local workshops provide opportunities to learn from shared experiences. This collaborative environment allows individuals to exchange tips, showcase designs, and receive constructive feedback, fostering an atmosphere of growth.

Additionally, staying updated on industry advancements through community participation helps ensure your techniques are current and effective. Networking with other DTF printers can lead to collaborations and mentorship opportunities, ultimately enhancing both skill sets and business viability.

Frequently Asked Questions

What are the best practices for DTF printing?

To achieve high-quality DTF prints, start by using quality materials such as premium inks and films. Pre-treat fabrics before printing to ensure better adhesion, conduct test prints to adjust settings, and follow curing instructions carefully. Experimenting with different fabrics can also yield unique results.

How can beginners get started with DTF printing?

For beginners in DTF printing, it’s crucial to choose a reliable printer designed for this technique. Invest in high-quality inks for vibrant colors, understand the importance of temperature and pressure settings, and begin with simple designs. Regular printer maintenance and staying updated on industry trends will greatly enhance your skill.

What are the do’s and don’ts of DTF printing?

Key do’s in DTF printing include using quality materials, conducting test prints, and ensuring proper curing. Don’ts include skipping printer maintenance, ignoring temperature settings, and using low-quality films, as these can significantly affect the quality of your prints.

What tips can improve the quality of DTF prints?

To ensure high-quality DTF prints, focus on maintaining your printer regularly, using high-grade DTF films, pre-treating fabrics properly, and experimenting with different fabric types. Additionally, documenting your settings and networking with other printers can provide valuable insights.

Why is proper curing important in DTF printing?

Proper curing is vital in DTF printing as it ensures that prints adhere correctly to the fabric and prevents issues like peeling and fading. Following the recommended curing guidelines will help maintain the durability and vibrancy of your designs.

How does the choice of printer affect DTF printing quality?

Selecting a high-quality printer specifically designed for DTF printing directly impacts the final output quality. A reliable printer will provide better precision, color accuracy, and adaptability, which are essential for producing crisp, vibrant prints consistently.

| Key Points | Description |

|---|---|

| DTF Printing Overview | DTF printing stands for Direct to Film printing and is popular for its vibrant and high-quality prints. |

| Key Do’s | Use quality materials, conduct test prints, pre-treat fabrics, and select the right printer for successful outcomes. |

| Key Don’ts | Avoid skipping equipment maintenance, overloading the printer, and using low-quality films to prevent issues. |

| Beginner Tips | Choose reliable printers, understand ink quality, and stay updated with trends. |

| Best Practices | Pre-treat fabrics, ensure proper curing, and maintain documentation of settings for continuous improvement. |

Summary

DTF printing techniques are essential for anyone venturing into the realm of custom apparel production. This method stands out due to its capacity to create stunning and durable designs that can elevate any clothing line. By adhering to the expert tips outlined in this guide, such as prioritizing quality materials, understanding the intricacies of equipment maintenance, and continually experimenting with different fabrics and designs, printers can achieve remarkable results. The emphasis on do’s and don’ts, tailored for both beginners and seasoned professionals, facilitates a deeper comprehension of the process, helping to refine skills in DTF printing. In summary, with careful attention to best practices and a commitment to learning, anyone can master the art of DTF printing to produce exceptional prints that truly stand out.