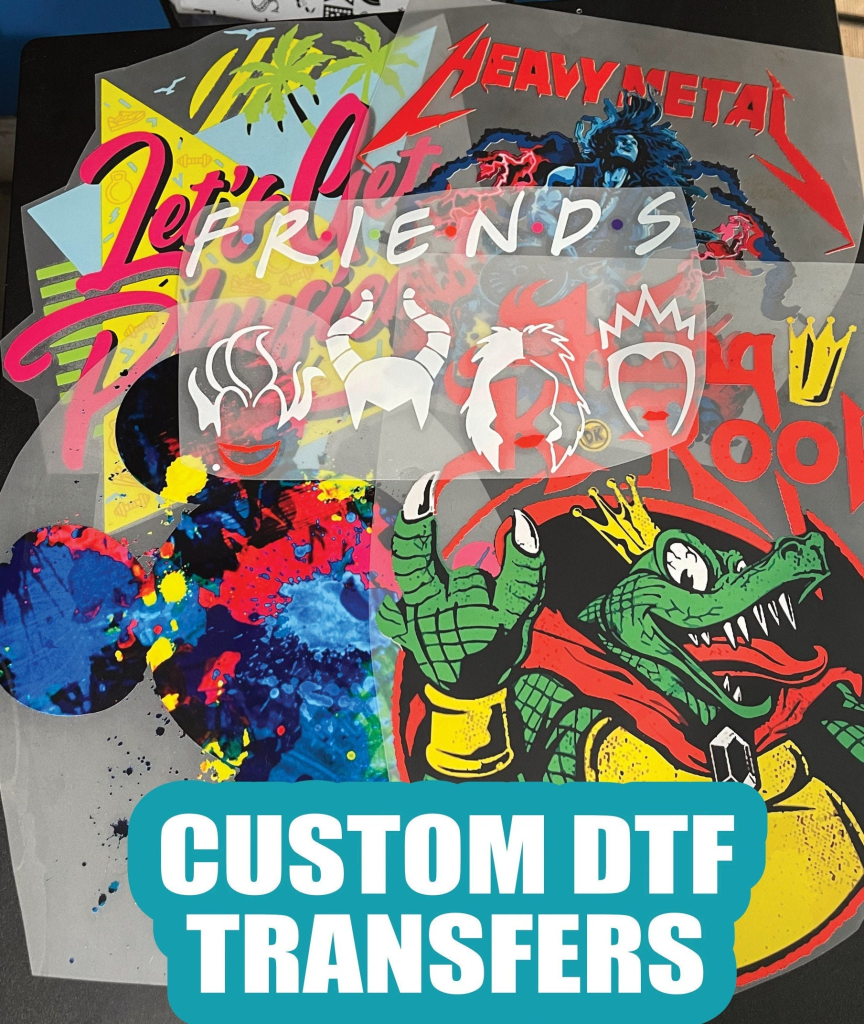

DTF transfers, or Direct-to-Film transfers, are revolutionizing the way we think about custom printing. This innovative printing method enables high-quality prints that are not only vibrant but also incredibly durable, making it ideal for various fabrics. Among its many advantages, DTF printing stands out by employing advanced techniques that ensure sharp, detailed images, elevating the visual appeal of custom apparel. The use of gang sheets in DTF printing allows for cost-efficient production, making it a popular choice for businesses seeking both quality and affordability. As demand for personalized products escalates, DTF transfers are becoming an essential tool for companies aiming to enhance their customization capabilities and streamline production processes.

Direct-to-Film printing, often referred to by its abbreviation DTF printing, serves as a modern solution in the realm of apparel customization. This method leverages cutting-edge inkjet technology to apply designs directly onto high-quality film, which can then be heat-pressed onto fabric. Given its versatility, recent trends have spotlighted DTF as a leading choice for those seeking stunning and long-lasting prints. Businesses are increasingly recognizing the benefits of using this technique over traditional approaches, such as screen printing, allowing for greater creativity and efficiency. As the custom apparel landscape evolves, the adoption of DTF provides a competitive edge, ensuring that the quality of prints meets the high standards expected by today’s consumers.

Understanding DTF Printing Technology

DTF printing, or Direct-to-Film printing, operates on a cutting-edge technological framework that combines digital printing with transfer techniques. This method streamlines the design process by allowing intricate graphics to be printed onto a specially coated film, which can then be transferred onto various substrates using heat press technology. The capability to diversify printing surfaces—from cotton to blends—opens a realm of possibilities for businesses specializing in custom apparel printing. As a result, more brands are leveraging DTF technology to provide vibrant, long-lasting prints that stand out in a saturated market.

Unlike traditional methods such as screen printing, DTF printing minimizes setup costs and enables quicker adaptations for multiple designs. This immediacy not only appeals to consumers seeking unique customizations but also supports businesses in responding to market trends instantly. The efficiency of the DTF process helps in decreasing turnaround times, making it an invaluable asset for any company wanting to thrive in the fast-paced custom print industry.

The Distinct Advantages of DTF Transfers

DTF transfers offer numerous advantages that make them particularly appealing to both large-scale and small-scale production outfits. One of the core benefits is their exceptional print quality. DTF technology utilizes high-quality inks that penetrate deeply into the film, resulting in prints that boast vivid colors and phenomenal detail. This level of clarity and brightness is maintained across various fabric types, meaning apparel designed with DTF transfers will resist fading or cracking even after many washes, a critical factor for customers.

Furthermore, the adaptability of DTF transfers to different fabric blends enables businesses to cater to a broad market. Brands looking to provide custom apparel can confidently use DTF printing on everything from t-shirts to hoodies to bags, enlarging their customer base and enhancing their product offerings. The precision and quality achievable with DTF make it a preferred method for promotional items that require eye-catching designs.

Cost Efficiency Through Gang Sheets in DTF Transfers

One of the shining features of DTF transfers is the utilization of gang sheets, which significantly enhance cost efficiency. Gang sheets involve consolidating multiple designs into a single film for printing, which helps minimize ink and film costs. This method of batch printing not only saves money but also reduces waste—leading to more sustainable production practices. For businesses looking to maximize their budget, employing gang sheets can be a transformative approach that drives profitability.

Moreover, by using gang sheets, companies can streamline their workflow and increase productivity. With the ability to print numerous designs at once, DTF technology allows for a more organized production line, ensuring that order fulfillment times are kept to a minimum. This feature empowers businesses to take on larger volumes of orders and expand their reach without the anxiety of overwhelming production methods.

Accelerated Production Times with DTF Transfers

The pursuit of rapid production has become paramount in the custom apparel industry, and DTF transfers excel in this aspect. The DTF process, when complemented with advancements in printing technology, enables businesses to significantly decrease their production time. For instance, the latest DTF printers, equipped with advanced features, are designed to handle high volumes without sacrificing quality, helping businesses meet their clients’ pressing deadlines.

The capability to quickly produce high-quality prints not only satisfies customer demands for fast service but also positions companies favorably against competitors who may still rely on slower printing methods. By incorporating DTF technology, businesses can offer quick turnaround times on custom prints, ultimately enhancing customer satisfaction and loyalty.

Accessibility of DTF Printing Platforms for Businesses

Recent developments in DTF printing platforms have made this technology more accessible to businesses of all sizes. Services like Snuggle DTF provide user-friendly interfaces that allow even those without extensive technical knowledge to manage and execute custom print orders seamlessly. This accessibility encourages entrepreneurship in the custom apparel space, empowering startups and small businesses to enter the market with affordable printing solutions.

By democratizing the printing process, these platforms allow a diverse array of creative expressions, expanding the universe of potential designs. Companies can now easily explore various aesthetics and cater to niche markets, such as personalized gifts or themed apparel, without the burden of complex technical setups. This user-friendly shift is key to innovation in custom apparel printing.

Future Trends: DTF Printing in the Custom Apparel Market

As the landscape of the custom apparel market continues to evolve, DTF printing shows signs of substantial growth and potential. The increasing emphasis on high-quality, personalized products places DTF technology at the forefront of this trend. Companies like EazyDTF, with investments in large-format DTF capabilities, are setting the stage for widespread industry adoption, indicating a bright future for this method as a standard for high-quality prints.

The long-term benefits of adopting DTF printing technology go beyond mere production efficiency; they also include enhanced customer satisfaction and loyalty. As businesses embrace digital printing trends and techniques, those that strategically incorporate DTF will likely distinguish themselves, maintaining a competitive edge in an ever-changing market. In essence, the foundations being laid by DTF innovation today will influence the direction of custom apparel printing for years to come.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct-to-Film printing, is a revolutionary method for creating high-quality prints. It involves printing designs onto a special film using advanced inkjet technology, which is then transferred onto various materials, such as cotton or polyester, using heat. This technique results in vibrant, durable prints that maintain their brilliance over time.

What are the advantages of DTF transfers for custom apparel?

DTF transfers offer numerous advantages for custom apparel, including exceptional print quality with sharp images and vivid colors. This technology also allows for the use of gang sheets, which reduce costs and waste by consolidating multiple designs onto one film, enhancing efficiency and sustainability in production.

How do gang sheets enhance DTF printing efficiency?

Gang sheets significantly improve DTF printing efficiency by allowing multiple designs to be printed on a single film sheet. This reduces material usage and costs, streamlining the production process for businesses. Lower waste and higher productivity make DTF transfers advantageous for custom apparel printing.

Are DTF transfers suitable for small and medium-sized businesses?

Yes, DTF transfers are highly suitable for small and medium-sized businesses due to their cost-effectiveness and quick production times. The ability to use gang sheets allows these businesses to maximize printing capabilities without sacrificing quality, making DTF an ideal choice for custom apparel markets.

What technologies are associated with DTF transfers?

Recent advancements, such as the LOKLiK iPrinter DTF-A3-XP600, showcase cutting-edge technology in DTF transfers. These printers offer efficient production times and high-quality outputs, making them valuable assets for businesses looking to leverage DTF printing for custom designs.

How has DTF printing made custom prints more accessible?

DTF printing has become more accessible through platforms like Snuggle DTF, which allow businesses without in-house capabilities to create and manage print orders online. This accessibility empowers a broader audience to utilize DTF transfers for high-quality custom apparel printing, even with limited technical expertise.

| Key Points | Description |

|---|---|

| Exceptional Print Quality | DTF transfers provide vibrant colors, sharp images, and detailed designs that hold up well on various fabrics. |

| Cost Effectiveness with Gang Sheets | Using gang sheets allows multiple designs to be printed together, reducing costs and waste. |

| Speedy Production Times | DTF printing technology enables quick turnaround times, making it ideal for businesses needing efficient production. |

| User-Friendly Platforms | Innovative platforms enhance accessibility, allowing even those without technical expertise to create high-quality prints. |

| Market Growth | The DTF printing market is expanding, with major investments indicating a growing demand for this technology. |

Summary

DTF transfers are redefining the landscape of high-quality prints in the custom apparel market. With exceptional print quality, cost efficiency through the use of gang sheets, and rapid production capabilities, businesses are increasingly adopting this advanced method. The accessibility of user-friendly platforms enables a broader range of creators to participate in this innovative printing solution. As DTF technology continues to evolve and grow in popularity, it positions itself as a go-to choice for high-quality customized products. Companies that embrace DTF transfers not only improve their operational efficiencies but also significantly enhance customer satisfaction, ensuring a competitive edge in the bustling custom printing industry.