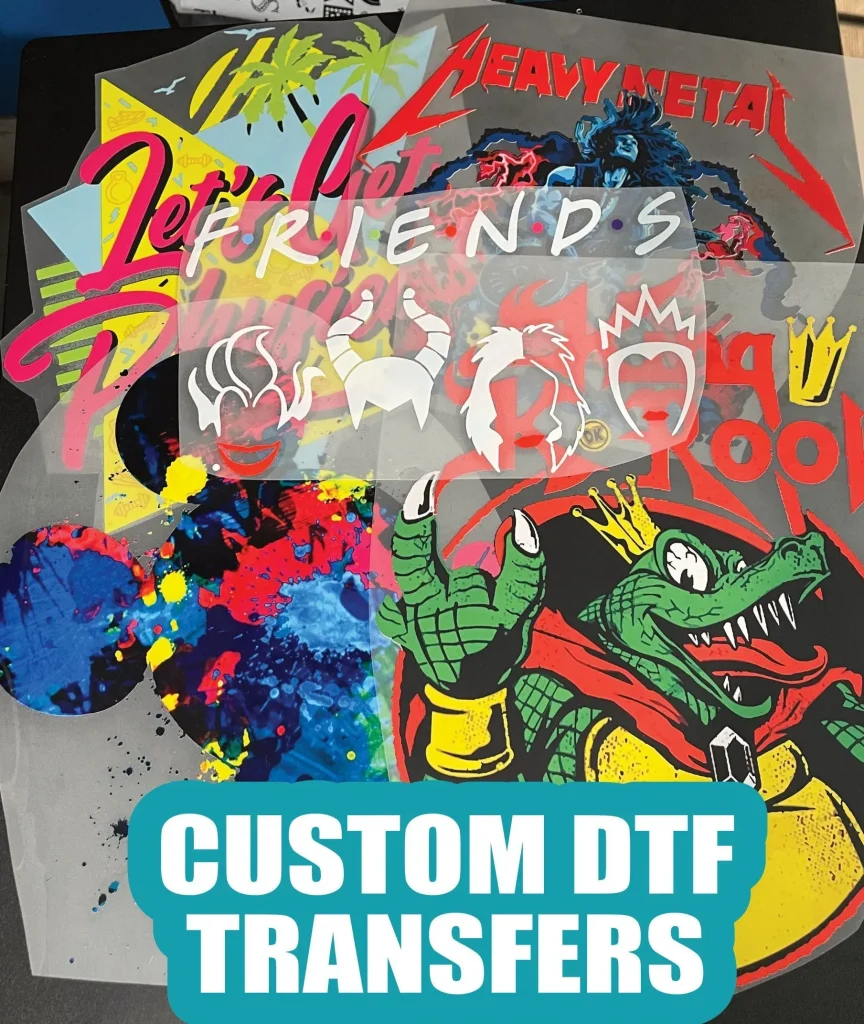

DTF transfers, or Direct to Film transfers, are revolutionizing the world of custom garment printing by providing an innovative solution for creating vibrant prints on various fabrics. This remarkable technique allows users, especially beginners, to explore digital printing’s possibilities while achieving exceptional detail and durability. In this beginner DTF guide, we delve into the essential equipment, processes, and care instructions necessary to master the DTF transfer technique. From the start of your printing journey to the final application on textiles, you’ll learn how to produce high-quality designs that stand out. Understanding the intricacies of DTF printing opens up a new realm for anyone looking to make their mark in the custom apparel industry.

Direct to Film printing—or DTF printing—is gaining traction among those involved in personalized garment production. This method leverages digital technology to create intricate designs that are easily transferred onto fabrics, offering versatility unmatched by traditional screen printing. Whether you’re a hobbyist or an aspiring entrepreneur, the DTF transfer technique enables you to produce vibrant prints that not only look stunning but also last. The approach is user-friendly, making it an excellent choice for those seeking a detailed, effective solution for custom garment printing. As we explore this captivating process, you’ll discover the tools needed to get started and the best practices to follow for optimal results.

Understanding the Basics of DTF Printing

DTF printing, or Direct to Film printing, is a modern garment printing technique that revolutionizes how designs are applied to fabric. Unlike traditional methods, DTF utilizes a special film to transfer vivid images directly onto textiles. This printing method is particularly advantageous for its ability to print on various types of fabrics, including cotton, polyester, and blends. The vibrant prints created through DTF are not only eye-catching but also durable, making them ideal for custom garment productions. Understanding the foundational aspects of DTF is crucial for those eager to dive into the world of custom apparel.

For beginners, grasping the concept of DTF requires a bit of technical knowledge and creativity. The process begins with designing artwork using software like Adobe Illustrator or CorelDRAW, which ensures high-resolution images that translate well onto the film. Once the design is prepared, it is printed onto a special film with water-based inks, which allow the transfer to maintain its integrity during the application process. By familiarizing oneself with these basics, newcomers can lay the groundwork for a successful journey into custom garment printing.

Essential Equipment for DTF Transfers

Starting your DTF printing journey necessitates investment in specialized equipment. The most important tool is the DTF printer, which needs to be equipped with water-based inks specifically formulated for this printing technique. This printer allows for detailed and colorful prints, which are the hallmark of DTF transfers. Furthermore, obtaining high-quality DTF transfer film is crucial, as the PET film used in the process is designed to optimize the adhesion and vibrancy of the print on different fabric types.

Another indispensable piece of equipment is the heat press, which allows for the correct application of heat and pressure during the transfer process. Look for a heat press that offers precise temperature control and even pressure distribution, as this greatly enhances the quality of the transfer. Having the right tools not only improves output quality but also streamlines the entire printing process, setting beginners up for success in their DTF endeavors.

Lastly, a reliable adhesive powder is necessary to ensure the transfer adheres effectively to the fabric. This powder must be applied while the ink remains wet and cured properly to achieve a solid bond between the design and the material. Mastery of these tools and techniques will elevate the beginner’s skillset and enable them to create remarkable DTF transfers.

Designing for Successful DTF Transfers

Successful DTF transfers begin with smart design preparation. Beginners should utilize graphic design software to create their artwork, ensuring that the images are not only high-resolution but also suitable for transfer. Adding intricate artwork or vibrant colors can make any design pop, drawing attention to the final product. It’s essential to consider the fabric type when designing, as this can influence colors and texture.

Another critical aspect of design preparation is the mirroring step before printing. Since DTF printing involves transferring ink onto a film that will eventually face down onto the fabric, properly mirroring the design is crucial. Skipping this step could lead to flipped or incorrectly oriented images on the final garment, which can be frustrating for beginners. By paying careful attention to these details, newcomers can ensure their DTF printed designs look polished and professional.

Optimizing the Printing Process

Once the design is prepared, optimizing the printing process is the next key step. Adjusting printer settings to match the specifications for DTF printing is essential; this includes selecting the correct paper type and ensuring the right ink saturation for vibrant color output. A poorly calibrated printer can lead to suboptimal results, making it essential for beginners to familiarize themselves with the printer’s capabilities and settings.

During the printing process, the choice of transfer film also plays a critical role in the final outcome. The film should be loaded correctly into the printer to avoid jams or misprints. Moreover, beginners must ensure that the ink saturates adequately to achieve rich colors on the adherence surface. Learning how to perform test prints and making necessary adjustments can significantly enhance the quality of the DTF transfers produced.

Applying DTF Transfers Effectively

After successfully printing your design onto transfer film, the next step is applying it to your chosen fabric. Proper application is key for durability and vibrancy. When using a heat press, it’s vital to preheat the machine to the recommended temperature, typically between 300 and 350°F. This ensures optimal adhesive activation and design adherence to the fabric, providing a lasting finish.

Additionally, using a protective sheet during the heat press application can prevent damage to the design and fabric. This extra layer helps in distributing heat evenly, minimizing risks of scorching or uneven application. Beginners should also allow the fabric to cool slightly before peeling off the film, as waiting too long can sometimes lead to the design sticking too tightly to the transfer film.

Caring for DTF-Printed Garments

To maintain the vibrant quality of DTF-printed garments, specific care instructions are essential. Washing in cold water and air drying is the preferred method to protect the print from fading. Beginners should inform their customers or themselves about the importance of washing garments inside out, which can significantly prolong the life of the print.

Furthermore, avoiding high heat settings when drying is crucial to preserving the design’s integrity. Adhering to these simple care guidelines keeps the prints looking fresh and vivid, ensuring customer satisfaction and repeat business. Creating a care label for custom garments enhances professionalism and shows commitment to quality.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct to Film transfers, are a modern printing technique that involves printing designs onto a special film. The printed film is then heat transferred onto various fabrics. This method allows for vibrant prints and intricate designs, making it ideal for custom garment printing.

What equipment do I need to start using DTF transfers?

To get started with DTF transfers, you’ll need a compatible DTF printer that works with water-based inks, special PET transfer film, and a heat press with adjustable settings. These tools are essential for achieving high-quality, durable prints on garments.

How do I prepare my design for DTF printing?

To prepare your design for DTF printing, use graphic design software to create or edit your artwork. Ensure the design is high-resolution, and don’t forget to mirror the design before printing, as it will be transferred from the back side of the film.

What are the main steps in applying a DTF transfer to fabric?

The main steps for applying a DTF transfer include printing your mirrored design onto transfer film, adding adhesive powder while the ink is still wet, curing the adhesive, and then using a heat press to transfer the design onto the fabric.

What are the care instructions for DTF-printed garments?

To preserve the quality of DTF-printed garments, wash them in cold water and air dry. Avoid using high heat settings when drying, and turn the garments inside out before washing to protect the vibrant prints.

What are the benefits of using DTF transfers compared to other printing methods?

DTF transfers offer numerous benefits, such as the ability to print on a variety of fabric types, achieving vibrant and detailed prints, and enhanced durability. This makes DTF printing an attractive choice for custom apparel and promotional items.

| Key Techniques | Description |

|---|---|

| 1. Equipment Required | Includes a compatible printer, special transfer film (PET), and a heat press for applying designs to fabric. |

| 2. Design Preparation | Utilizes graphic design software to create artwork, ensuring high-resolution and mirroring the design before printing. |

| 3. Printing the Design | Adjust printer settings for DTF printing and print the mirrored design onto the transfer film. |

| 4. Applying the Transfer | Add adhesive powder to wet ink, then cure the adhesive following specific instructions. |

| 5. Transferring to Fabric | Use a heat press at recommended settings to transfer the design to the fabric, then peel off the film. |

| 6. Post-Press Care | Provide washing instructions to maintain print quality; avoid high heat during drying. |

Summary

DTF Transfers are an innovative method in the custom printing world that allows for the creation of high-quality designs on a variety of fabrics. This technique excels in versatility, enabling artists and businesses alike to produce vibrant prints that last. By understanding the fundamentals—from the right equipment and software to the detailed steps of applying transfers—beginners can harness DTF printing to enhance their projects and offerings. As the DTF technology evolves, staying up to date with trends will further empower creators in the custom garment space, ensuring they can deliver exceptional prints that meet customer expectations.