In the vibrant realm of custom apparel, DTF Transfers, or Direct-to-Film Transfers, are transforming the way designs are printed and applied. This revolutionary DTF printing technology simplifies the printing process, allowing businesses to create vibrant, high-quality graphics on a variety of fabrics. As demand for unique custom apparel grows, understanding DTF transfers becomes vital for entrepreneurs seeking innovative solutions. This guide offers a comprehensive look into everything you need to know about DTF transfers, including their advantages, applications, and insights into leading DTF printing services. Whether you are a small business or a larger brand, DTF transfers can elevate your product offerings and meet the demands of your customers.

Custom printing methods such as Direct-to-Film (DTF) technology have gained significant traction in recent years, highlighting a shift towards more versatile and dynamic printing solutions. DTF printing services offer businesses the chance to create intricate designs on various fabric types without the limitations of traditional printing techniques. This approach not only ensures high-quality visuals but also provides durability and longevity in printed apparel. As more brands delve into the realm of custom apparel through the use of DTF transfers, understanding the nuances and benefits of this method becomes crucial for thriving in today’s competitive market. In this complete guide, we will explore the fundamentals of DTF techniques, offering insights into their applications and potential for innovation.

Understanding Direct-to-Film Transfers (DTF)

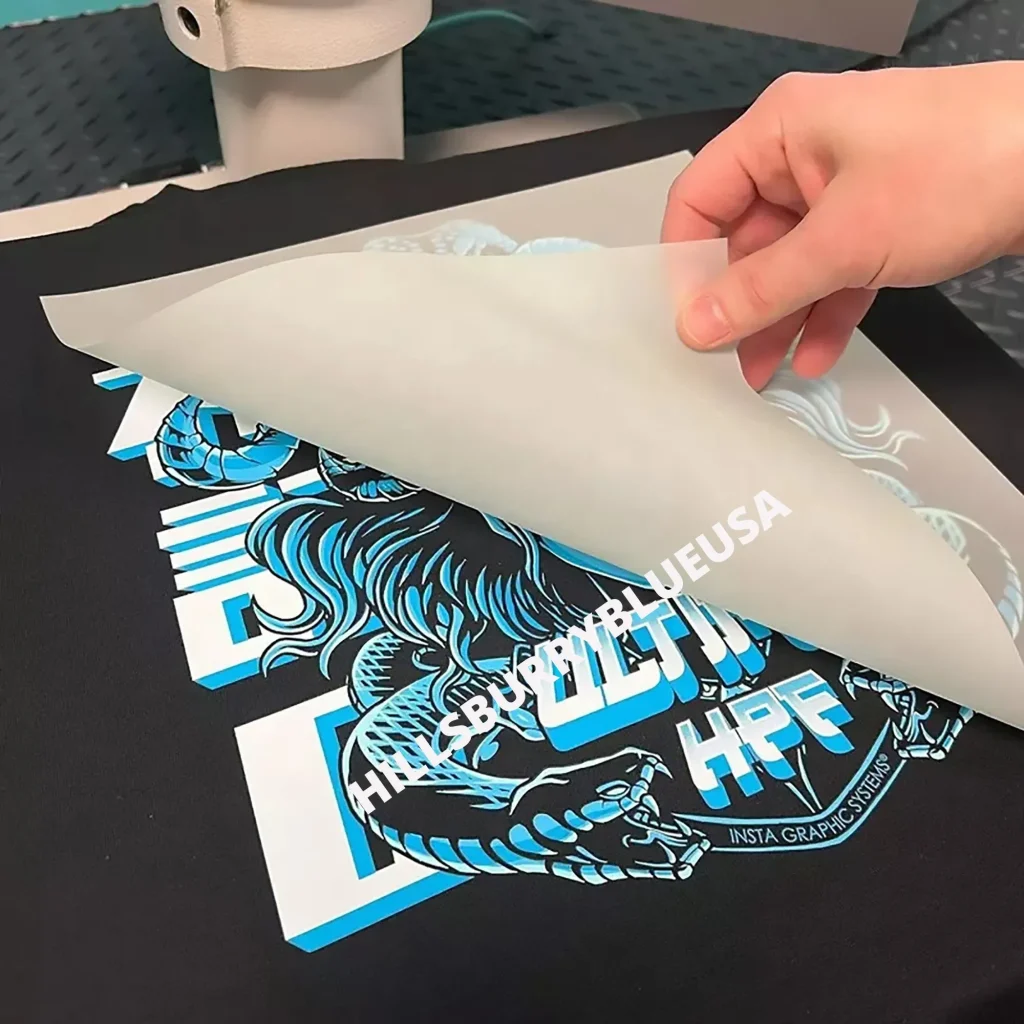

Direct-to-Film (DTF) Transfers have become a buzzword in the custom printing world, revolutionizing the way designs are applied to fabric. This technology employs a unique method where images are printed onto a specially coated film, allowing for high-definition and vibrant designs that capture the essence of custom apparel. The film is then transferred onto various materials under heat and pressure, creating a bond that ensures durability and quality. This innovative approach not only enhances the aesthetic appeal of garments but also expands the possibilities for customization, inviting a wider range of creative expressions.

The process of DTF printing sets itself apart from more traditional methods like screen printing or direct-to-garment (DTG) by allowing for finer details and a broader color palette. This makes DTF especially suitable for intricate designs that require precise representation, such as logos, detailed graphics, or multicolor images. As a result, businesses that specialize in custom apparel can meet the growing consumer demand for personalized products that stand out in a competitive marketplace.

Benefits of DTF Printing Technology

DTF printing technology brings forth a multitude of advantages that can significantly benefit businesses in the apparel industry. One of its most notable benefits is the remarkable print quality that can be achieved. DTF transfers are designed to produce vibrant colors and crisp details, reflecting accurate color representation that is crucial for brand identity. As a result, companies can offer high-quality products that appeal to consumers seeking unique and eye-catching designs.

Another benefit is the versatility of DTF transfers. Unlike traditional methods, which may have limitations based on fabric types, DTF technology can be applied to a diverse range of materials, including cotton, polyester, and even blends. This adaptability not only expands the creative scope for artists and designers but also allows businesses to cater to different market segments with ease. From t-shirts to athletic wear, DTF transfers can be a game-changer for custom apparel offerings.

The Durability of DTF Transfers

Durability is a critical factor in the custom apparel industry, and DTF transfers excel in this area. The prints produced via DTF technology are known for their resistance to fading, peeling, and cracking over time. This is particularly advantageous for items that undergo frequent washing and wear, as consumers increasingly seek reliable products that maintain their appearance and quality through numerous washes.

Moreover, the robust nature of DTF transfers does not compromise the softness of the fabric. Users benefit from a comfortable wearing experience without the stiff feeling often associated with other printing techniques. Such durability ensures customer satisfaction and loyalty, making DTF printing services an attractive option for both businesses and end-users.

Applications of DTF Transfers in Custom Apparel

The applications of DTF transfers in the realm of custom apparel are vast and varied. From promotional merchandise and team uniforms to fashion pieces and personalized gifts, DTF technology is proving to be a versatile toolkit for creativity. This method facilitates the quick turnaround of unique designs that cater to diverse consumer needs, whether it is for small batches of custom orders or larger bulk prints.

Furthermore, DTF transfers enable businesses to explore creative avenues in fashion trends and personalized styles. With the rise of ‘fast fashion’, being able to offer unique, custom designs on demand is increasingly valuable. Whether it’s for corporate branding, special events, or individual expressions of style, DTF transfers equip businesses to meet and exceed customer expectations in a rapidly evolving market.

Innovations and Trends in DTF Printing Services

The landscape of DTF printing services continues to evolve, fostering innovations that enhance efficiency, print quality, and user satisfaction. Companies such as Sam’s DTF Transfers are leading the charge by implementing cutting-edge equipment and techniques that streamline the printing process. The rise of automated systems and improved ink formulations has resulted in faster production times and enhanced durability of prints, helping businesses keep pace with growing demand.

In addition to efficiency improvements, new design software and tools are emerging to make the DTF workflow smoother. These innovations allow designers to create, edit, and prepare files for printing more seamlessly than ever. As a result, businesses can expect not only better quality prints but also a much more user-friendly experience, empowering them to focus on creativity while leaving the technical aspects to the latest technology.

Future Projections for DTF Transfers in Custom Printing

Looking ahead, the future of DTF transfers appears bright, as consumer trends favor personalization in apparel. As technology advances, we can anticipate even greater enhancements in the DTF printing process, from reduced production times to the introduction of eco-friendly inks that align with sustainability goals. This makes DTF a compelling choice for businesses aiming to cater to environmentally conscious consumers while still delivering high-quality products.

The potential for DTF technology to dominate the custom printing landscape is also bolstered by emerging platforms that facilitate e-commerce and on-demand printing services. In this new era of digital commerce, DTF transfers are well-positioned to meet the demands of personalization, allowing businesses to scale effectively while remaining responsive to market trends. Embracing these advancements will be essential for brands that wish to capitalize on the growing popularity of customized apparel.

Frequently Asked Questions

What are Direct-to-Film Transfers (DTF Transfers) and how do they work?

Direct-to-Film Transfers (DTF Transfers) involve printing designs onto a special film that is then transferred onto fabric using heat and pressure. This method ensures vibrant colors, intricate designs, and durability, making it ideal for custom apparel across various materials.

What are the advantages of using DTF printing technology for custom apparel?

DTF printing technology offers several advantages for custom apparel, including high-quality prints with vivid colors, versatility across different fabric types, durability against fading and peeling, and the option for no minimum orders, making it accessible for small businesses.

How does DTF printing differ from traditional printing methods?

DTF printing differs from traditional printing methods in its approach to transferring designs. DTF transfers use a specialized film and heat press technique, allowing for more vibrant colors and intricate details on a wider range of materials compared to methods like screen printing or direct-to-garment (DTG) printing.

What do I need to consider in a DTF transfer guide when starting my custom printing business?

When consulting a DTF transfer guide, consider factors such as the type of printer and materials needed, techniques for applying transfers, quality assurance measures, and best practices for maximizing the durability and vibrancy of your prints on various fabrics.

Are there any limitations to using DTF transfers for custom apparel designs?

While DTF transfers are versatile, some limitations may include the need for specific heat settings based on fabric type and potential issues with adhesion if not applied correctly. It’s essential to follow recommended guidelines to ensure the best results with DTF printing technology.

Where can I find reliable DTF printing services for my business?

You can find reliable DTF printing services by researching companies with positive reviews and proven expertise in the field. For instance, Sam’s DTF Transfers is recognized for its high-quality in-house printing services with no minimum order requirements, catering to various business sizes.

| Key Point | Description |

|---|---|

| What are DTF Transfers? | A printing technique that uses heat and pressure to transfer vibrant designs from a specially printed film to fabric. Ideal for various materials, including cotton and polyester. |

| Key Advantages | 1. High Quality Prints – Ensures vivid colors and fine details. 2. Versatile Application – Suitable for multiple fabric types. 3. Durability – Resistant to fading, cracking, and peeling. 4. No Minimum Orders – Greater accessibility for small businesses. |

| Recent Developments | 1. Sam’s DTF Transfers: Leading provider with no minimum orders. 2. Insta Graphic Systems: Introduced innovative heat transfer products. 3. FESPA Expo: Highlights advancements with the Mimaki UJV300DTF-75. 4. DTF Expo: Showcasing heat transfer innovations. 5. Practical Challenges: Addressing durability and removability of DTF prints. |

| The Future of DTF Transfers | Growing demand for custom apparel positions DTF transfers at the forefront of printing technology, with potential expansions through roll-to-roll systems for efficiency. |

Summary

DTF Transfers are revolutionizing the world of custom apparel, offering businesses a robust and innovative solution for high-quality printing. With their ability to produce vibrant, durable prints on a variety of fabrics without requiring minimum order quantities, DTF technology is accessible for both small and large enterprises. As leading companies enhance their DTF processes and address challenges like print durability, the future of DTF Transfers looks promising. By remaining aware of industry trends and technological advancements, businesses can capitalize on the growing demand for personalized apparel, ensuring they remain competitive in the evolving custom printing market.