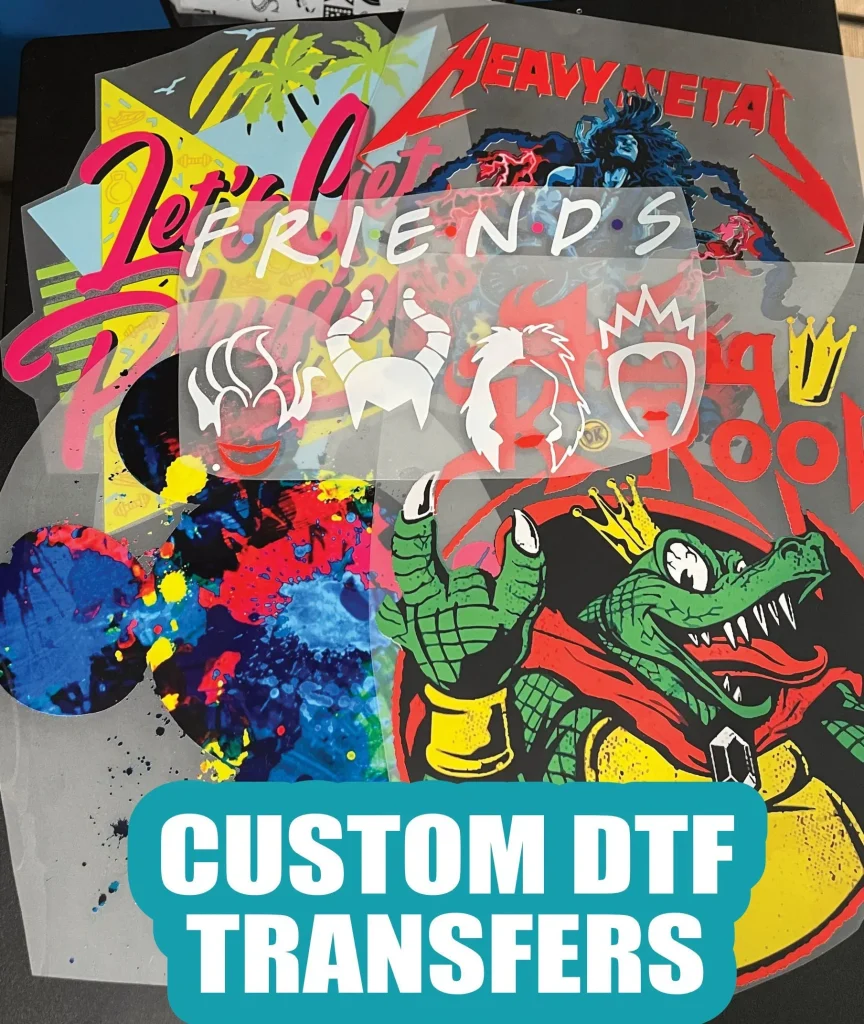

DTF transfers, or Direct-to-Film transfers, are revolutionizing the printing landscape by providing a modern, efficient solution for custom apparel. This innovative printing technology stands out due to its ability to produce vibrant, high-quality images on a wide range of fabrics, making it a top choice for businesses seeking effective screen printing alternatives. With a focus on ease of use, DTF transfers streamline the printing process, enabling entrepreneurs and small businesses to create professional designs without massive overhead. As the demand for personalized merchandise grows, embracing DTF printing becomes a cost-effective and strategic move for those in the custom fashion industry. By combining reliability, versatility, and quality, DTF transfers are setting a new standard in garment decoration, making them an essential consideration for anyone looking to stay ahead in the competitive market.

Direct-to-Film printing has emerged as a groundbreaking method in the world of textile decoration, providing an array of options for businesses and creatives alike. Often referred to simply as DTF printing, this technique offers a unique way to transfer intricate designs onto garments by utilizing film technology. Not only does this method cater to the rising trend of personalized apparel, but it also serves as a more accessible alternative to traditional screen printing methods. With its efficient process and high-quality outcomes, DTF printing is quickly becoming a preferred choice for many looking to innovate in the custom apparel market. As the printing industry evolves, DTF transfers are defining a new path, effectively bridging the gap between quality and affordability.

Understanding DTF Transfers and Their Mechanics

Direct-to-Film (DTF) transfers represent a modern marvel in the world of printing technology. This innovative process allows businesses to print high-resolution images directly onto a special film, which is then heated and transferred onto fabric. Unlike traditional screen printing methods that require intricate setups and multiple layers, DTF technology simplifies the printing process, considerably reducing overhead and labor costs for businesses. As the demand for quality customization in the apparel industry increases, understanding the mechanics of DTF transfers becomes crucial for anyone looking to stay competitive.

The simplicity of DTF transfers is one of the key factors contributing to their growing popularity in custom apparel. The process involves printing a design onto the film, applying an adhesive powder, and then heat pressing it onto the desired fabric. This user-friendly approach is particularly appealing to newcomers and smaller businesses that may lack extensive experience with more complex printing methods. As a result, DTF printing has not only democratized access to high-quality printing but has also enriched the tapestry of creative expression within the fashion landscape.

Why DTF Printing Outshines Traditional Methods

When comparing DTF transfers to traditional printing methods such as screen printing, the advantages are striking. DTF printing offers a significant enhancement in terms of color vibrancy and design details. While screen printing allows for bulk production of designs, it often struggles with intricate patterns and color gradients. DTF transfers, on the other hand, easily accommodate detailed graphics, making them ideal for custom apparel that requires specificity and finesse.

In addition to superior quality, DTF transfers also boast greater versatility across a range of fabrics, including cotton, polyester, and even leather. As businesses and designers further explore the possibilities of fabric types and styles, DTF printing emerges as a solution that caters to a wider audience. With the ability to print directly onto various materials, DTF technology fulfills both the needs of entrepreneurs and the diverse preferences of customers, effectively setting a new standard in the printing industry.

Cost-Effectiveness of DTF Transfers

Cost efficiency is one of the most compelling reasons businesses are transitioning to DTF transfers. As technology improves and printer prices drop, more entrepreneurs have the opportunity to invest in DTF printing without breaking the bank. DTF printing minimizes waste and reduces inventory costs since designs can be printed on demand, aligning perfectly with today’s trend of sustainability and responsible manufacturing.

The low initial investment and reduced labor make DTF printing an attractive alternative for startups and small businesses. Rather than spending significant funds on intricate setups required for screen printing, business owners can produce high-quality prints with minimal resources, amplifying profit margins while maintaining quality standards. This financial incentive has made DTF transfers a game-changer in the world of custom apparel, allowing brands to thrive in a competitive marketplace.

The Role of DTF Transfers in Custom Apparel Demand

The rise of e-commerce has transformed the custom apparel landscape, with consumers increasingly seeking unique designs that reflect their personal style. DTF transfers are perfectly positioned to cater to this burgeoning demand, offering fast turnaround times and the ability to produce custom designs without the limitations often encountered in traditional screen printing. As ecommerce businesses strive to meet consumer expectations, the flexibility of DTF printing allows them to remain agile in their offerings.

Moreover, the capacity for high-quality, low-run productions means entrepreneurs can experiment with different lineups and trends without financial strain. Customers are drawn to the unique opportunities presented by DTF transfers, leading to higher engagement and brand loyalty among businesses that can provide personalized items swiftly and efficiently. DTF technology not only fulfills consumer needs but also enables businesses to stay relevant and forward-thinking in an evolving marketplace.

Innovations Fueling DTF Transfer Technology

The future of DTF transfers is bright, spurred by ongoing innovations in printing technology. Recent advancements in inks and transfer films contribute to prints that are not only vibrant but also incredibly durable. These breakthroughs ensure that DTF prints can withstand multiple washes without fading, which is vital for brands aiming to maintain product quality and customer satisfaction over time.

In addition, as researchers develop eco-friendly inks that align with global sustainability initiatives, DTF transfers are becoming even more attractive to environmentally conscious businesses. The ability to produce high-quality, sustainable prints positions DTF technology at the forefront of printing solutions, appealing to consumers who prioritize environmental responsibility in their purchase decisions. This innovative progress places DTF transfers as a primary choice for future garment decoration, ensuring they remain relevant as market demands shift.

The Environmental Advantages of DTF Printing

As sustainability takes center stage in various industries, DTF transfers offer a compelling alternative to traditional printing methods that often generate significant waste. The efficiency of the DTF printing process allows for reduced material waste, as designs can be printed only as needed, eliminating surplus stock that can contribute to environmental degradation. Businesses embracing DTF technology are playing a critical role in fostering sustainable practices within the custom apparel sector.

Furthermore, the reduced need for extensive cleaning agents and water in the DTF printing process also contributes to a lower overall environmental impact. By prioritizing eco-friendly methods and minimizing waste, businesses that adopt DTF technology not only enhance their brand image but also appeal to a growing base of environmentally aware consumers. The integration of sustainability with high-quality printing creates a unique selling proposition for companies looking to establish themselves as leaders in responsible manufacturing.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing high-quality designs onto a special film, which is then heat pressed onto textiles. This process offers a user-friendly approach, allowing for vibrant prints on a variety of materials, including cotton and polyester, making it a popular choice in the custom apparel market.

How do DTF transfers compare to traditional screen printing?

DTF transfers are often seen as a superior alternative to screen printing due to their ability to produce detailed designs rapidly and with less setup. While screen printing is labor-intensive and time-consuming, DTF technology streamlines production, catering to businesses looking for cost-effective printing solutions with quick turnaround times.

Are DTF transfers a sustainable printing option?

Yes, DTF transfers are considered a more sustainable printing option compared to traditional methods. The process produces less waste and allows for on-demand printing, reducing surplus inventory. As eco-friendliness becomes crucial, DTF technology is evolving with environmentally conscious inks and practices.

What is the cost-effectiveness of DTF printing for small businesses?

DTF printing is notably cost-effective for small businesses due to the lower initial investment and operating costs. As the technology advances, affordable DTF printers have entered the market, enabling startups to produce high-quality custom apparel without significant overhead, enhancing their profitability.

Can DTF transfers be used on various fabric types?

Absolutely! DTF transfers are versatile and can be applied to a wide range of fabrics, including cotton, polyester, and more specialized materials like leather. This adaptability makes them a fitting choice for businesses that aim to offer diverse custom apparel options to their customers.

What advancements can we expect in DTF transfer technology?

The DTF transfer technology is expected to see significant advancements, particularly in the development of eco-friendly inks and improved transfer films that enhance print durability and washability. As the demand for customization and sustainability grows, innovations will continue to shape the future of DTF printing.

| Key Point | Details |

|---|---|

| Overview of DTF Transfers | DTF printing involves transferring high-quality images onto textiles using a special film, making it accessible for small businesses and startups. |

| Ease of Use | The simple process allows even beginners to produce professional-quality garments with ease. |

| Quality and Versatility | DTF prints offer vibrant colors and detailed designs suitable for various fabric types. |

| Market Insights | The DTF market is growing rapidly due to increased demand for sustainable and customized apparel. |

| Cost Efficiency | Reduced costs of DTF technology attract smaller businesses aiming for profitability. |

| Technological Advances | Innovations in DTF inks enhance the durability and washability of prints. |

| Customer Demand | E-commerce growth has led to a demand for fast, custom printing solutions. |

| Environmental Impact | DTF printing reduces material waste and can help lower a business’s environmental footprint. |

| Future Predictions | The sector is expected to grow with advancements in eco-friendly inks and materials. |

Summary

DTF transfers are set to revolutionize the printing industry by offering a modern, efficient, and sustainable alternative to traditional methods. This innovative technology simplifies the process of printing high-quality custom designs on various textiles, making it more accessible to small businesses and entrepreneurs. As consumer demand for personalized products continues to grow, DTF transfers align perfectly with market trends, ensuring businesses can meet customer needs quickly and efficiently. With the added benefits of cost-effectiveness and environmentally friendly practices, DTF transfers not only contribute to enhanced profitability for businesses but also promote a more sustainable approach to print production.