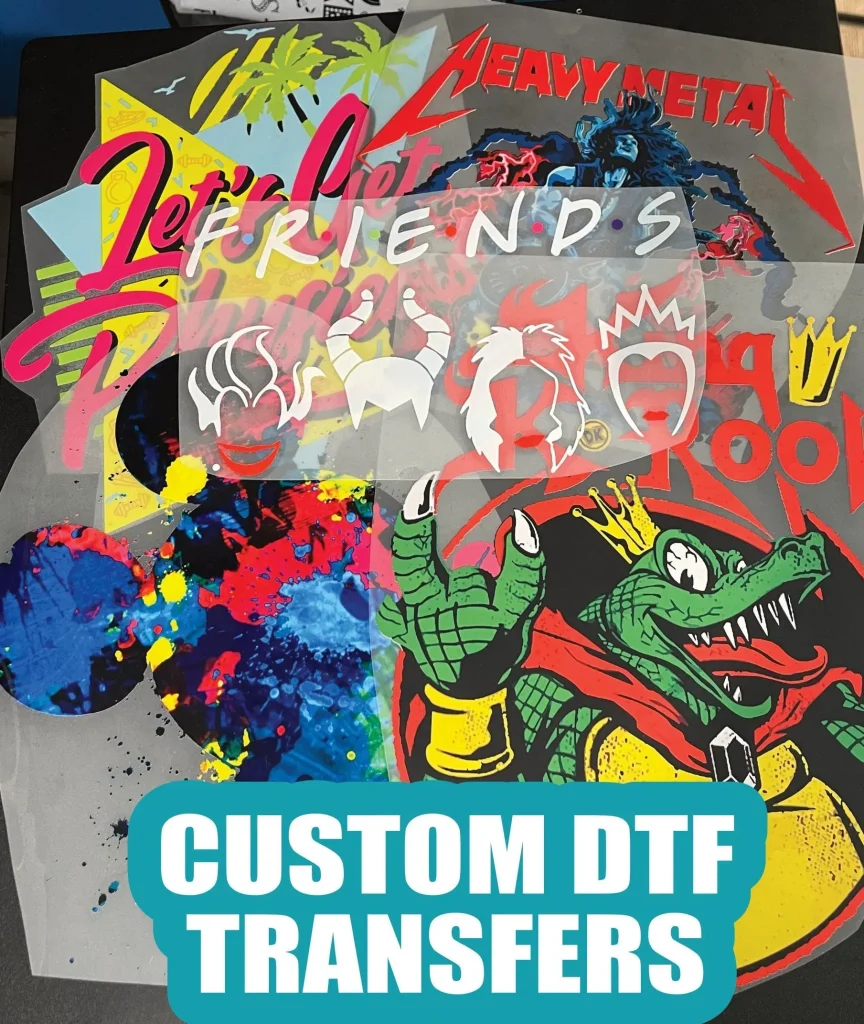

In the vibrant world of custom apparel printing, DTF transfers are emerging as a game-changer for artists and businesses alike. Direct-to-Film (DTF) technology allows for exquisite designs to be transferred seamlessly onto a wide array of fabrics, combining versatility with impressive print quality. Unlike traditional methods, DTF transfers produce vivid colors and a soft finish, making them ideal for those seeking high-quality results without compromise. As small businesses increasingly adopt this innovative printing technique, the demand for DTF transfers continues to soar, redefining how we think about apparel decoration. This guide will explore the nuances of DTF printing, highlighting its advantages, process, and future trends in the dynamic landscape of custom apparel.

When discussing methods for applying stunning designs to textiles, terms such as Direct-to-Film printing or DTF technology are becoming synonymous with quality and efficiency. This advanced printing technique enables designers to create intricate graphics that can be easily transferred onto various materials with a high level of precision. Thanks to its user-friendly nature, entrepreneurs and print professionals are finding that DTF transfers provide a compelling alternative to traditional apparel printing approaches. Whether you refer to it as DTF transfers, film printing, or even garment decoration, the focus remains on delivering exceptional print quality for custom apparel that stands out in a competitive marketplace.

Understanding DTF Technology

DTF technology stands apart from other apparel printing methods due to its innovative approach to transferring designs. Unlike traditional screen printing, which relies on stencils and ink layers, DTF uses water-based inks that are printed onto a unique film, allowing for intricate designs with ease. This technology allows for the ability to print complex graphics and vibrant colors on a diverse range of fabrics such as cotton, polyester, and blends, without the extensive setup costs associated with methods like screen printing.

With its revolutionary nature, DTF printing is not only favored for its print quality but also for its eco-friendly approach. The inks used in DTF transfers are typically water-based, significantly reducing the environmental impact compared to some other printing technologies that use solvent-based inks. As industries move towards more sustainable practices, DTF technology is poised to take center stage in the apparel printing arena, attracting both new businesses and established brands looking to innovate in custom apparel.

Benefits of Using DTF Transfers in Apparel Printing

One of the most compelling benefits of DTF transfers is their cost-effectiveness for small businesses and start-ups in the custom apparel sector. The initial investment for DTF equipment is generally lower than traditional screen printing setups, allowing entrepreneurs to produce high-quality prints in smaller batch sizes. This flexibility encourages creativity and experimentation with designs without the financial pressure of large minimum orders, making it an attractive option for custom apparel printing.

Furthermore, DTF technology excels in delivering print durability. Unlike other printing techniques that may fade or peel over time, garments printed with DTF can withstand numerous washes while maintaining their vibrancy. This quality assurance not only enhances customer satisfaction but fosters loyalty as buyers appreciate the longevity and exceptional quality of their customized attire.

Exploring DTF Printing Process

The DTF printing process, while straightforward, requires precision in each step to ensure high-quality outputs. The journey begins with design preparation, where graphic designers use specialized software to create print-ready files. Once ready, the designs are printed onto a heat-resistant film with DTF inks, an essential aspect of maintaining color vibrancy on different fabric types. Following this, adhesive powder is meticulously applied and melted to create a robust transfer.

Heat transfer is the final stage of the DTF process where the printed film is applied to the fabric using a heat press. The temperature and pressure must be carefully managed to achieve a successful transfer and avoid any damage to the garment. This process not only enhances the print’s adherence but plays a crucial role in ensuring that the design appears crisp and clear, emphasizing the need for expertise in executing each step.

Current Market Demand for DTF Transfers

The demand for DTF transfers is rapidly increasing as more consumers seek unique and personalized apparel options. This rise can be attributed to the growing trend of customization in fashion, where individuals want to stand out with custom apparel that reflects their personal styles. Industry reports suggest that businesses investing in DTF technology are better positioned to compete in a crowded marketplace by offering tailored solutions that cater to the preference for bespoke clothing.

Moreover, as fashion and technology converge, many brands are adopting DTF printing due to its ability to reduce production times and enhance turnaround efficiency. This trend is especially beneficial for e-commerce platforms and small businesses that rely on quick delivery of customized orders. The ongoing advancements in DTF technology, such as enhancements in ink formulations and printing speeds, reflect a promising future trajectory within the garment printing industry, making DTF a vital player.

Common Challenges Faced in DTF Printing

Despite its numerous advantages, DTF printing comes with its own set of challenges. A primary concern is the learning curve for new users unfamiliar with this technology. Understanding the intricacies of the DTF process, from design adjustments to managing the heat transfer parameters, requires time and experience to master. Many beginners can struggle with achieving consistent results, leading to potential frustrations during the early stages of their printing journey.

Quality control is another significant challenge in DTF printing. Variations in fabric types can influence how the prints adhere and appear after transfer. Many users discover that what works well on one fabric may not yield the same results on another, necessitating thorough testing and adjustment of the settings for different fabrics. By honing their skills and conducting regular quality checks, businesses can mitigate these challenges and ensure only the best products reach their customers.

Getting Started with DTF Printing Resources

For those eager to embark on their DTF printing journey, a wealth of resources is available to guide beginners. Comprehensive guides, like those offered by *Nations Business*, break down the crucial elements needed to start printing, from equipment selection to effective design strategies. These resources provide insightful tips to navigate the complexities of the DTF process, ensuring newcomers have a solid foundation to build upon.

Additionally, platforms such as *Printavo* offer essential insights into the cost structures associated with DTF printing and practical advice on setting up a successful printing business. Learning from seasoned professionals can provide newcomers with a roadmap to avoid common pitfalls and capitalize on opportunities within the custom apparel market. With the right resources, aspiring DTF printers can confidently launch their ventures and thrive in this innovative space.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

Direct-to-Film (DTF) transfers are a modern apparel printing method that involves printing designs onto a specialized film, which is then heat-pressed onto fabric. This process allows for intricate, high-quality prints that are vibrant and durable, making DTF an ideal choice for custom apparel.

What advantages does DTF printing technology offer compared to traditional printing methods?

DTF printing technology provides several advantages over traditional methods like screen printing, including lower setup costs, ease of use, and the ability to print on various fabric types without sacrificing print quality. DTF transfers are cost-effective and produce soft, vivid designs that withstand multiple washes.

How is print quality maintained in DTF transfers?

The print quality in DTF transfers is maintained through precision in the printing process. The use of high-quality DTF inks and a specialized printing method ensures sharp, vibrant imagery. Additionally, the heat transfer process bonds the design robustly to the fabric, contributing to durability and softness.

Are there any challenges associated with DTF transfers in apparel printing?

While DTF transfers are advantageous, challenges include a learning curve for new users who must master the heat transfer process, and potential variations in print quality based on different fabric types. Consistent results may require practice and adjustments during setup.

What types of fabrics can DTF printing be used on?

DTF printing is versatile and can be used on a variety of fabrics, including cotton, polyester, and blended textiles. This flexibility makes DTF transfers an excellent option for a wide range of custom apparel products.

How can one get started with DTF printing for custom apparel?

To get started with DTF printing, one should research essential supplies and equipment such as DTF inks, heat presses, and specialized software for design preparation. Resources like guides and tips from experienced printers can also provide valuable insights into launching a successful DTF printing business.

| Key Points | Details |

|---|---|

| What is DTF Transfers? | A printing method where designs are printed onto film and then applied to fabric using heat. |

| Advantages | Cost-effective, high-quality prints that are user-friendly and durable. |

| Current Market Trends | Increasing demand for custom apparel and significant investments in DTF technology by manufacturers. |

| Challenges | Steep learning curve for beginners; quality control issues with varying fabric types. |

| Resources for Beginners | Guides from Nations Business and Printavo for tools and techniques in starting DTF printing. |

Summary

DTF Transfers are reshaping the landscape of apparel printing by introducing a method that is not only innovative but also practical and affordable. This technique allows for vibrant, high-quality prints that require minimal startup costs, making it accessible to both small business owners and printing enthusiasts. As the demand for personalized clothing continues to rise, and as technology evolves, DTF transfers represent a sustainable and effective solution for those looking to enhance their custom apparel offerings.