UV DTF transfer materials empower creators to achieve durable, vivid finishes on a wide range of fabrics. This approach enables vivid prints with UV DTF, thanks to high color density and tight gradients. By pairing durable DTF inks and films with a reliable transfer film and adhesive powder, you’ll boost washfastness. When comparing UV DTF vs traditional DTG, you may notice crisper edges and better performance on a wider range of fabrics. For best results, choose the best DTF transfer film and powder that work with DTF transfer materials for fabrics.

Alternatively, this technique is often described as UV-curable ink-on-film printing for textiles. In practical terms, the workflow uses a printable transfer film, photopolymer inks cured by ultraviolet light, and an adhesive powder to bond designs to fabric. Compared with dye-based DTG methods, this approach delivers durable color, sharp outlines, and better compatibility with synthetic substrates. Other LSIs for this topic include UV-curable transfer media and photo-activated film systems, all aimed at high color fidelity on cotton, blends, and performance fabrics.

UV DTF transfer materials: Building a durable, vivid print workflow

UV DTF transfer materials enable a streamlined workflow that combines UV-curable inks, a reliable transfer film, and an adhesive powder. This trio delivers high color density, crisp edge definition, and strong washfastness across a broad range of fabrics, making it easier to achieve professional results in modest production sets.

To maximize durability and vibrancy, establish a repeatable process: prepare substrates to reduce moisture and wrinkles, calibrate color profiles for accurate reproduction, cure the UV inks promptly, apply adhesive powder evenly, and optimize heat-press parameters. A consistent workflow minimizes variability and helps you realize the full potential of durable DTF transfer materials.

Durable DTF inks and films: How to pair inks and films for long-lasting results

Durable DTF inks and films form the foundation of lasting prints. Select UV DTF inks designed for high color fastness and opacity on dark fabrics, paired with a transfer film offering clean release, minimal dot gain, and strong dimensional stability under heat and pressure. When these two elements are matched well, colors stay vibrant after many washes.

In practice, testing combinations on representative fabrics helps you verify color density, opacity, and edge fidelity. A well-chosen pairing reduces reprints and ensures that the final result remains faithful to the original design across multiple cycles, emphasizing the importance of durable DTF inks and films in your material mix.

UV DTF vs traditional DTG: Choosing the right approach for fabrics

Understanding UV DTF vs traditional DTG helps you select the best method for a given substrate and production goal. UV DTF can deliver sharper edges and stronger color saturation on a wider range of fabrics, including poly blends, with reduced risk of dye migration common in some DTG inks. The durability of the UV-curable process often yields a more robust bond after heat-pressing.

However, the choice between UV DTF and DTG depends on substrate, production volume, and the desired fabric hand. For certain projects, UV DTF offers faster cure, fewer post-processing steps, and easier expansion to non-traditional textiles, while DTG may still be preferred for soft hand on specific cotton blends. Considering UV DTF transfer materials alongside DTG options helps you optimize both cost and outcomes.

Achieving vivid prints with UV DTF: Color management and film selection

Achieving vivid prints with UV DTF begins with color management and selecting the right film. A wide color gamut, strong dark tones, and smooth gradients hinge on ink formulation, while the transfer film preserves color integrity during heat application. A high-quality film helps maintain edge crispness and reduces unwanted halos.

Practical steps include calibrating printers with test panels, verifying white point accuracy, and managing skin tones across diverse fabrics. Pairing the inks with an appropriate transfer film and ensuring proper curing yields vivid prints with UV DTF that stay true through repeated washes.

Best DTF transfer film and powder: Finding the right combination for your fabrics

Selecting the best DTF transfer film and powder is essential for durable, clean transfers. The powder should melt and bond evenly to the printed image, enabling a robust transfer without clumping or affecting the hand feel. Likewise, the transfer film should release cleanly, preserve image fidelity, and withstand the heat-press process.

When evaluating options, consider substrate compatibility, cost, and throughput. Testing different film chemistries and powder weights on your most-used fabrics—from cotton tees to blends—helps identify a reliable combination that minimizes reprints while maximizing color fidelity and durability.

DTF transfer materials for fabrics: Compatibility across cotton, blends, and performance fabrics

DTF transfer materials for fabrics must work across a wide spectrum of textiles, including 100% cotton, cotton blends, polyester, and performance fabrics. Substrate compatibility governs adhesion, hand feel, and washfastness, so choose inks, films, and powders proven to perform under your common production conditions.

In practice, this means validating the full material set on your top fabrics, monitoring color density and feel after transfer, and adjusting cure times as needed. A careful, fabric-first approach—supported by durable DTF transfer materials and tested workflows—helps ensure consistent results across orders and fabric types.

Frequently Asked Questions

What are UV DTF transfer materials and why are they durable for fabrics?

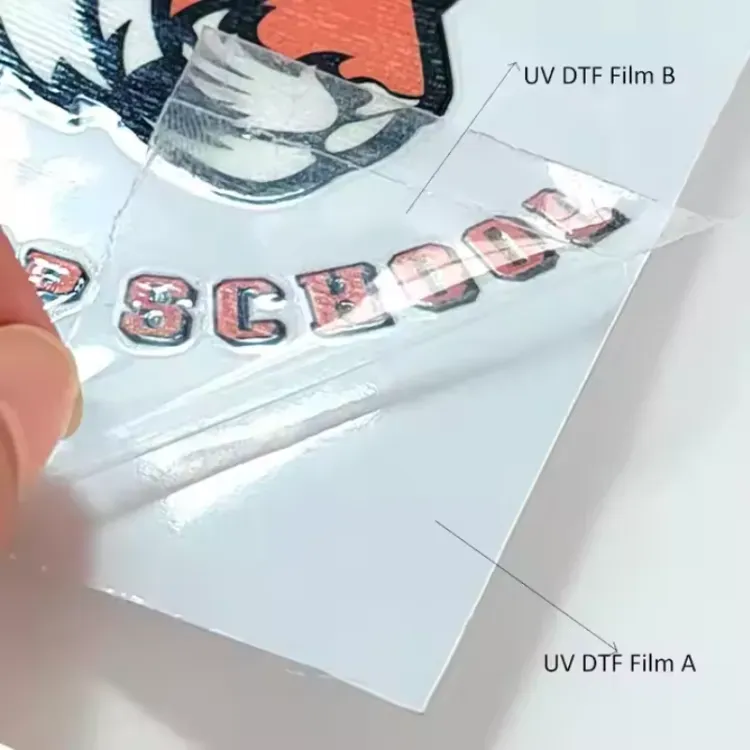

UV DTF transfer materials are a three-component system consisting of UV-curable inks, a transfer film (PVC-free or PET), and an adhesive powder. When printed and cured under UV light, these inks produce dense, vivid images that bond strongly to fabrics through the adhesive powder, delivering durable, wash-fast results. Pairing durable DTF inks and films with the right powder helps maintain color and edge definition across multiple washes.

How does UV DTF transfer materials compare to traditional DTG in terms of vibrancy and durability? (UV DTF vs traditional DTG)

UV DTF transfer materials typically offer sharper edges and higher color saturation, with strong performance on a wider range of fabrics compared to traditional DTG. The UV-curable process creates a robust bond during heat pressing, contributing to durability and wash-fastness, while preserving vivid prints with UV DTF.

What should I look for when selecting the best DTF transfer film and powder for UV DTF transfer materials?

Look for high-opacity UV DTF inks, a transfer film with clean release and minimal dot gain, and an adhesive powder that evenly bonds to the substrate. Prioritize compatibility with your fabrics, low haloing, and a balance of cost and throughput to ensure you’re choosing the best DTF transfer film and powder for your UV DTF transfer materials.

Are UV DTF transfer materials suitable for dark fabrics and multiple wash cycles?

Yes, UV DTF transfer materials are suitable for dark fabrics and can withstand multiple wash cycles when properly cured and pressed. Using high-coverage inks and a reliable film/powder combination helps maintain vivid prints with durable adhesion on diverse fabrics.

Can UV DTF transfer materials be used on a range of fabrics (cotton, blends, polyester) while maintaining vivid prints?

Yes. UV DTF transfer materials are versatile for fabrics such as cotton, cotton blends, and polyester. Achieving vivid prints with UV DTF depends on substrate prep, color management, and selecting compatible inks, films, and powders designed for fabrics.

What is a simple, reliable workflow for using UV DTF transfer materials from printing to bonding?

A reliable workflow: print with UV DTF inks on the transfer film, cure under UV light, apply an even layer of adhesive powder, heat-press the image onto the fabric at the recommended temperature, time, and pressure, then allow to cool and cure as needed. This workflow leverages UV DTF transfer materials for durable, vivid results on a range of fabrics.

| Aspect | Key Points |

|---|---|

| What UV DTF transfer materials are | Three core components: UV-curable inks, a PVC-free or PET transfer film, and an adhesive powder. Inks cure instantly under UV, enabling dense color and sharp edges. |

| Main components | Inks with high color density and opacity on dark fabrics; a film that releases cleanly and withstands heat; powder that bonds well; ensure compatibility between components. |

| How UV DTF improves prints | Instant UV cure reduces smudging and enables tight color control; higher color density and smoother gradients; durable washfastness; vivid colors with sharp edges. |

| UV DTF vs DTG | Sharper edges and better color saturation on a wider range of fabrics; faster cure and less post-processing; typically more durable; suitability depends on substrate, volume, and feel. |

| Workflow basics | Prepare substrates, calibrate color management, set proper cure settings, apply powder evenly, optimize heat-press parameters, and plan post-press care. |

| Choosing best components | Look for inks with high density and fast cure; film that releases cleanly; powder that bonds without residue; test substrate compatibility; balance upfront cost with throughput. |

| Troubleshooting tips | Edge cracking: adjust heat/pressure and ensure even powder; color shifts after washing: verify cure and fabric compatibility; white ink opacity: ensure proper cure; dark fabrics: increase color density and/or powder. |

| Real-world applications | Athletic teams, boutique brands, and merch shops rely on UV DTF transfer materials for durable, vivid prints across fabrics; consistency reduces reprints and stock issues. |

| Maintenance and safety | Regular cleaning of print heads, color calibration, proper ink/film storage; ventilate work area; follow PPE guidelines; educate customers on care to preserve vibrancy. |

Summary

UV DTF transfer materials offer a compelling path to durable, vivid prints across a wide range of fabrics. By pairing UV-curable inks, a reliable transfer film, and an adhesive powder, shops can achieve sharp edges, dense color, and strong washfastness. The UV curing process enables rapid production, tighter color control, and easier multi-application use compared with traditional DTG on many substrates. When selecting components and refining workflow, prioritize ink density and opacity, film release quality, substrate compatibility, and consistent curing. While UV DTF transfer materials won’t replace every method, they provide a powerful combination of color fidelity, durability, and versatility for modern garment decoration. Test across your common fabrics, optimize heat-press parameters, and maintain safety and equipment to sustain high-quality results that endure washes.